Pharma packaging

Overview

Blister packaging machines and filling plants

In packaging plants of the pharmaceutical industry, polymer products from igus are used from the dosing station up to the labelling unit.Regardless of whether this involves the blister packaging of tablets or the filling of pharmaceutical bottles: The bearing technology must always meet the highest hygienic standards and thus, for example, function reliably in maintenance-free dry operation without the use of lubricants.

Used products and application examples

Below, exemplary stations of blister packaging machines and filling plants for pharmaceutical products and the igus products used are shown: Among others, iglidur plain bearings, igubal pillow block bearings, drylin linear bearings, lead screw technology or tribo-tape liners were installed here.1. Dosing station

2. Weighing station

3. Circular filler / Rotary table (only for filling systems)

4. Film positioning (only for blister packs)

5. Cutting mechanism (only for blister packs)

6. Labelling station

1. Dosing station

In the filling unit, drylin R linear guides are used in cam-guided circular fillers.

2. Weighing station

iglidur P plain bearings in the flap bearing arrangement in the weighing station are maintenance-free and cost-effective.

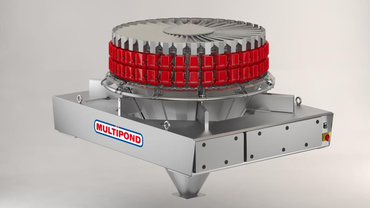

3. Circular filler / Rotary table

So that medicine bottles can be fed cleanly and without tipping over from the turntable to the subsequent stations, the surfaces are lined with the liner iglidur tribo-tape.

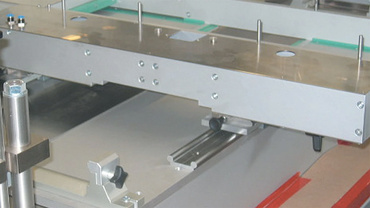

4. Film positioning

When positioning films in a blister machine, the advantages of flat, lubrication-free drylin W linear guides certified for use in cleanrooms are needed.

5. Cutting mechanism

drylin W linear bearing technology is used in the cutting mechanism for the blister foil. It operates completely lubrication-free and maintenance-free.

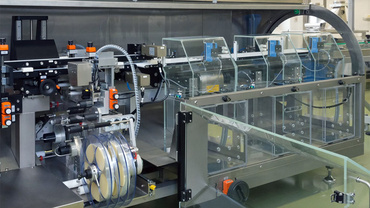

6. Labelling station

The seal labelling of blister packs can be flexibly adjusted using drylin bearing technology.Application examples of our customers

Transport technology rotary table

With the help of tribo-tape liner, plastic injection bottles are smoothly guided from a rotary table onto a conveyor belt.go to user report

Cutting station for blister packs

Plastic products in the cutting mechanism for blister packaging are maintenance-free and have good torque resistance.go to user report

Labelling station

The drylin linear systems ensure the flexible adjustment of this labeller for the pharmaceutical, food and cosmetics industries.go to user report

Blister packaging machine / Cartoner

The igubal pillow block bearings, lead screw nuts and lead screws enable precise adjustment mechanisms in this cartoner for blister packaging.go to user report

Position adjustments for blister packs

Lightweight and hygienic drylin linear bearings perform position adjustments in this pharmaceutical packaging machine.go to user report