Examples of successful applications in the machine tool industry

You can find an overview of application examples with igus products in machine tools

Application examples by challenge:

CNC machines: overview of applications

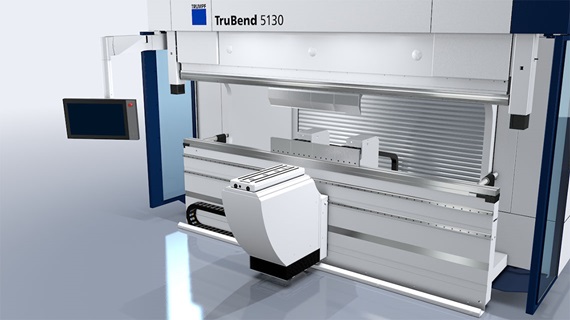

CNC (computerised numerical control) machines are indispensable in today's material machining processes. Using computer technology in industrial machining, not only enhances precision and manufacturing quality in workpiece machining, but also greatly increases productivity. Today, CNC-supported machines are used in a wide range of applications. This is a selection of CNC milling, drilling, grinding, turning, cutting, polishing and bending machines which use our energy chains, linear guides and plain bearing systems.Energy tubes in bending machines

Welding system

Combination machine for milling and drilling

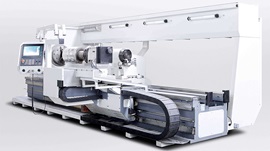

Horizontal lathe

This turning machine uses a guidelok e-chain on a travel of up to 20m. It is perfect for long unsupported travels in swarf areas.

Machining centre

Multi-spindle lathe

Compact milling machine

Milling machine for bicycles

Adverse environmental conditions (use of chemicals, high incidence of dirt, flying swarf)

Aggressive environmental conditions usually arise when metals are abrasively machined. Metallic swarf and lubricating oil collection affect elements such as cable guidance and linear guide systems. To operate machines with as few interruptions and as little downtime as possible, closed energy chains or energy tubes are often used to protect the cables inside them.

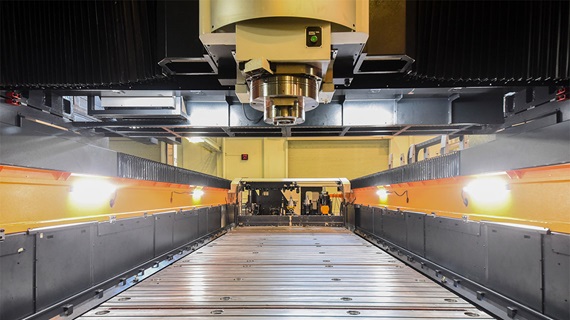

Energy tubes in milling machines for heavy-duty milling

Large machining centre gantries are the speciality of machine tool builder Kao Ming in Taiwan. The long travel lengths of up to 13 metres provide challenging requirements for the supply of energy and media. By choosing the guidelok, Kao Ming decided in favour of a system that is reliable, robust and operates without support.

Heavy-duty lathe

Cutting unit

Milling machine

Polishing machine

Lathes and milling machines

Flame cutting machine

Machining centre

Portal milling machine

Tight installation spaces and minimal bend radii

In refining machine tools, design engineers are always looking for ways to combine more powerful systems with space-saving solutions. This not only allows reduction of the overall system dimensions, but also provides considerable savings potential for the energy costs arising in ongoing operation. For instance, energy chains in such contexts must allow tight bend radii at high travel speeds and accelerations.

chainflex cables supply KESSLER spindles with energy and signals

The "system technology" business area of the renowned spindle manufacturer FRANZ KESSLER, develops and produces swivelling spindle heads and rotary pivoting tables, which enable a very precise processing of metal and increasingly also composite workpieces. Kessler uses chainflex solutions for the energy and signal supply as they meet the very high demands regarding service life and reliability.

Servo stamping and bending machine

High performance turning machine

Drilling machine

Gear grinding machine

Realising a vertical lift of over 1m and a pivoting range of 270° in a confined installation space was made possible in this application in the grinding head of a gear grinder.

Multi-spindle machining centre

This application involves a two-spindle horizontal machining centre equipped with exceptionally quiet and low-vibration energy supply systems.

Press automation system

This press automation system requires extremely space-saving energy supply at high speed.

Heavy-duty portal machine

Here, a simple trick was used to save space: there was only 20cm of installation height, which was too low for a conventional e-chain solution.

Machine tool for metal machining

In a machine tool operated by Yamazaki Mazak Corp., a machine builder, two e-chains run side by side, supplying energy in a very tight installation space.

Stretch-bending machine

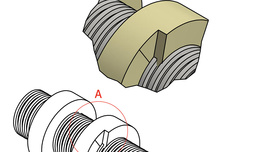

This lack of installation space necessitated forced guidance of the energy tube in this CNC inclined-bed turning lathe. Here, energy tubes ensure three-dimensional media supply.

Milling centre

This application is a swivelling head for a milling centre. In a very tight installation space, energy chains supply a number of media to the milling head.

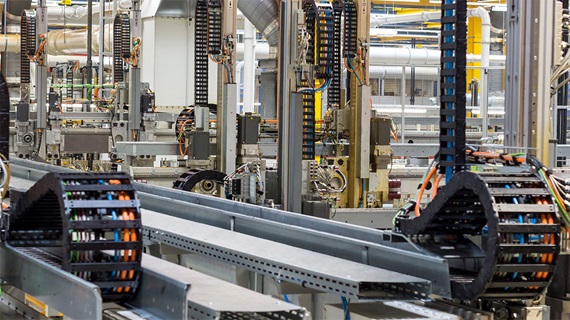

Long service life in continuous operation

During machine tool development, the focus was on high availability. Downtime was to be reduced, allowing customer operation that was as economical as possible. The high-quality systems would frequently be used in three-shift operations, seven days a week, and had to handle these demands with no problems. The customer focus for the following application examples was on energy chains, linear guides, and plain bearings that remained reliable under the high, constant movement loads.

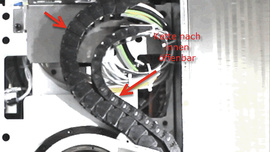

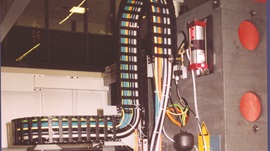

Energy chains and abrasion monitoring in the engine plant

There is scarcely any other industry in which reliability is so important as in the automotive industry. Because production downtime is so expensive, fail-safe components are important for vehicle manufacturers and suppliers. An Austrian engine manufacturer therefore relies on "smart plastics" from igus. Sensors measure wear during operation and notify the user early enough to plan a repair or an exchange.

Milling machine

CNC automatic multi-spindle lathe

Large processing centre

Cutting machine

Turning and grinding machines

Excellent condition even after nine years – pre-assembled energy supply systems are used in these precision machines under aggressive environmental conditions.

Friction stir welding machine

A closed R4 energy tube is in use 24 hours a day, seven days a week in a Grenzebach Maschinenbau GmbH friction stir welding machine.

Positioning systems in electronics manufacturing

This positioning unit uses a readychain system to reliably guide drive, measuring system, and compressed air lines – 24 hours a day, seven days a week.

Concrete pipe cutter

This milling machine ejects aluminium swarf, wood chips and fine dust from composite materials. It uses energy chains and bearing technology that must function reliably.

Machines for micro-assembly

These micro-assembly machines manage millions of work cycles each year. Energy chains and chainflex cables have shown themselves to be reliable system components under this constant load.

Quick, simple assembly

Modern machine tools require several months from assembly to commissioning. To get to normal operation faster, the highly complex systems will ideally be ready to go within a few weeks. Well-thought-out modular products, competent consultation and supplier base reduction contributed to this goal for the following applications.

readychain® chains reduce CNC system processing costs

In its robotic machining centres, Taiwanese tool manufacturer Hartford uses fully harnessed energy chain systems. This cuts out many process steps for the manufacturer, reducing assembly time from several weeks to just half a day. At the same time, customers can always depend on receiving a safe and reliable solution from a single source when they order readychains.

Machine tool series

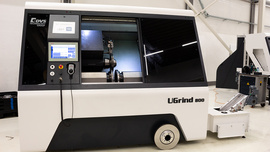

Grinding machine

An extremely smoothly running chain allows this CNC machine to operate precisely. A simple design minimises installation and maintenance costs.

Portal milling machine

The company gets everything from one source and directly from the manufacturer with pre-assembled readychain energy supply systems. This reduces installation time and costs.

Machining centre

The E4/4 light energy chain offers compact external dimensions and has a very robust design. The readychain system greatly facilitates installation, saving the customer time and money.

Gantry machining centre

The energy supply for this machining centre was designed to minimise the number of interfaces. The pre-assembled complete solution ensures that installation requires little time and money.

Grinding machine

The linear guides and polymer plain bearings used in this grinding machine require no maintenance or lubrication and ensure an especially long machine service life.

Other user reports

General machine tools

Replacing metallic bearings with iglidur polymer bearings allowed Deckel Maho Gildemeister to reduce the costs of its machine tools by more than 50%.

Water jet cutting system

Toothed belt unit with guide system

Parker EME uses drylin guide systems in its "LCB" linear actuator. They are extremely robust, have optimum wear and coefficient of friction properties, and require no lubrication.

Wire-bending machine

The SPEEDMAX bending machine series combines extremely high cyclic performance with minimum strokes. Because the load is so great, the customer uses robust iglidur plain bearings.

Machining centre

In today's machine tools and machining centres, lightweight, robust, lubrication-free polymer bearings are installed in a wide variety of locations. They function reliably despite the many machine movement cycles.

Laser cutting machine

This laser cutting machine is remarkable for such features as high travel speeds and accelerations. Energy chains in this application are dynamic and robust in their function.