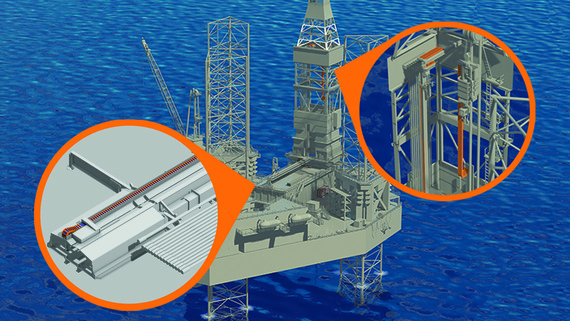

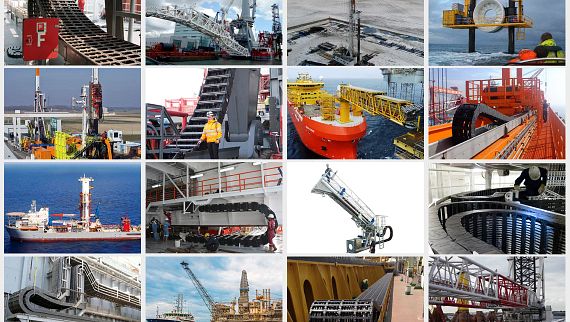

Energy chains and cables for pipe and BOP handling systems

Long horizontal and vertical travels are typical for pipe handling systems, for example to guide the drill pipe from the fingerboard to the top drive. Our plastic energy chains and cables are designed for the harsh conditions on drilling platforms and for aggressive external environmental influences. The cable guides have lower dead weight than steel chains do, and their corrosion resistance combined with high robustness also plays a role here, even with large additional loads. The plastic inner surfaces of the energy chain are cable-friendly and ensure especially reliable, maintenance-free systems.

Our engineering team takes care of the correct design of the energy chains and the problem-free connection to the customer's system, even for complete turnkey systems.

Products for:

Catwalks ▼ | Pipe handlers ▼ | BOP handling systems ▼

Our engineering team takes care of the correct design of the energy chains and the problem-free connection to the customer's system, even for complete turnkey systems.

Products for:

Catwalks ▼ | Pipe handlers ▼ | BOP handling systems ▼

Energy chains and cables for catwalks

A catwalk is used to move the drill pipe to the work platform (drill floor). To push it up, small carriages run along the ramp. They are often operated with hydraulic cables that are guided in energy chains.

Energy chains in catwalks must ensure the safe movement of all cables, sometimes on long travels.

Offshore drilling rigs are subject to especially harsh environmental conditions, such as corrosive sea air. In addition, e-chains are found on various telescopic units in which sensor or motor cables have to be moved.

Energy chains in catwalks must ensure the safe movement of all cables, sometimes on long travels.

Offshore drilling rigs are subject to especially harsh environmental conditions, such as corrosive sea air. In addition, e-chains are found on various telescopic units in which sensor or motor cables have to be moved.

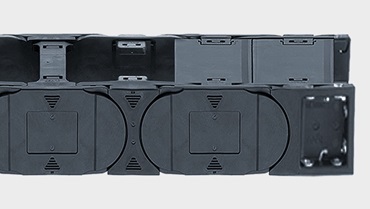

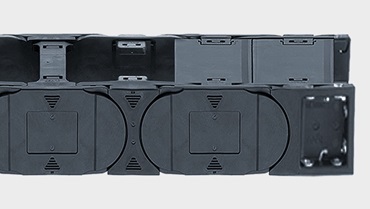

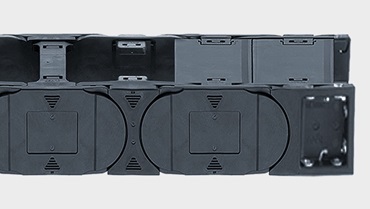

E4.80 e-chain

- The interior separation modular system increases your cables' service life by up to a factor of 4

- For long travels (up to 400m) and fill weights of up to 80kg/m

Find out more about E4.80

E4.56 e-chain

- The interior separation modular system increases your cables' service life by up to a factor of 4

- For long travels (up to 400m) and fill weights of up to 62kg/m

More about the E4.56 e-chain

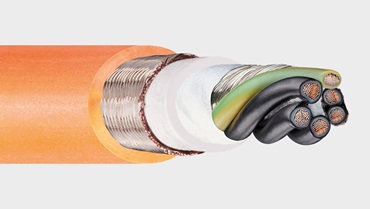

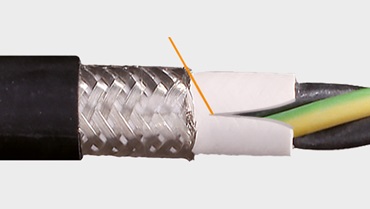

CF27 servo cable

- For extremely heavy duty applications

- Almost complete resistance to oil (based on DIN EN 50363-10-2)

- Flame-retardant and UV-resistant

Find out more about CF27 chainflex

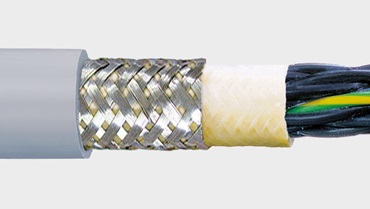

CF112 data cable

- For extremely heavy duty applications

- Almost complete resistance to oil (based on DIN EN 50363-10-2)

- Flame-retardant and UV-resistant

Find out more about CF112 chainflex

CF78.UL control cable

- For heavy-duty applications

- Almost complete resistance to oil (based on DIN EN 50363-10-2)

- Flame-retardant and UV-resistant

Find out more about chainflex CF78.UL

Energy chains and cables for pipe handlers

The pipe handler is used to move the drill pipe from a horizontal position from the catwalk to the vertical fingerboard, where it is finally stored for later use. Energy chains are also used here, allowing the pipe handler both to travel vertically and be positioned horizontally for precise storage of the drill pipe in the fingerboard.

It is especially important that the vertical routing of the heavy cables be safe on its long travel path. Plastic energy chains have an especially great advantage here, since they reduce the total weight hanging on the pipe handler thanks to their low dead weight.

E4.56 e-chain

- The interior separation modular system increases your cables' service life by up to a factor of 4

- For long travels (up to 400m) and fill weights of up to 62kg/m

More about the E4.56 e-chain

CF112 data cable

- For extremely heavy duty applications

- Almost complete resistance to oil (based on DIN EN 50363-10-2)

- Flame-retardant and UV-resistant

Find out more about CF112 chainflex

CF35.UL motor cable

- For extreme heavy duty applications

- Almost complete resistance to oil (based on DIN EN 60811-404)

- Flame-retardant and UV-resistant

Find out more about chainflex CF35.UL

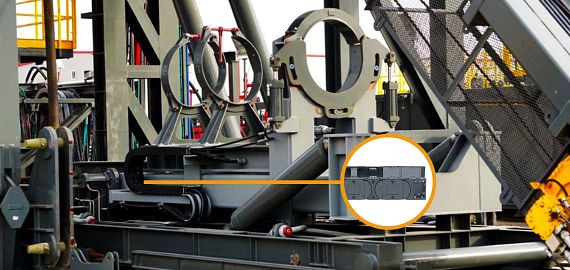

Energy chains for BOP handling systems

BOP handling systems are used to move or erect the blow-out preventer (BOP). Hydraulic adjustment systems are often used here, with hydraulic cables being moved with the frame. For offshore drilling rigs, BOP cranes are significantly larger than in onshore drilling rigs.Our E4 energy chains enable the often heavy cables to move smoothly, even over long travels, and protect them from mechanical loads and tangling.

E4.56 e-chain

- The interior separation modular system increases your cables' service life by up to a factor of 4

- For long travels up to 400m and fill weights up to 62kg/m

More about the E4.56 e-chain

Success stories

Energy chains for fingerboard assembly

Several plastic energy chains from the E4.1 series guide a large number of energy and data cables and hydraulic lines on two drilling vessels. They allow horizontal drill rod handling, for example, to equip the fingerboard.Learn more

... and other success stories

Heavy-duty energy chains in drilling rigs for such systems as the top drive, cantilever, or pipe handler; flexible rotary modules in pivoting heavy-duty cranes; or safe shore power supplies: Find out more about how our motion plastics are used in these and other projects.Discover now