Ready-to-install system solution consisting of energy chains and linear bearings in 3D printers

Whether rapid prototyping or mass production - 3D technology offers fascinating possibilities.

- What was needed: Plastic energy chains from the micro chain series, chainflex cables, drylin linear axes, drylin E stepper motors

- Requirements: Little installation space requires space-saving products and tight bend radii. In addition, the high dynamics in 3D printers require components that allow high accelerations and move precisely.

- Industry: 3D printer

- Success for the customer: The energy chain, cables and bearing technology including the motor result in a completely ready-to-install operating unit for the customer, which is optimally adapted to the high performance in 3D printers.

Everything from a single source: System solutions for the 3D printing industry

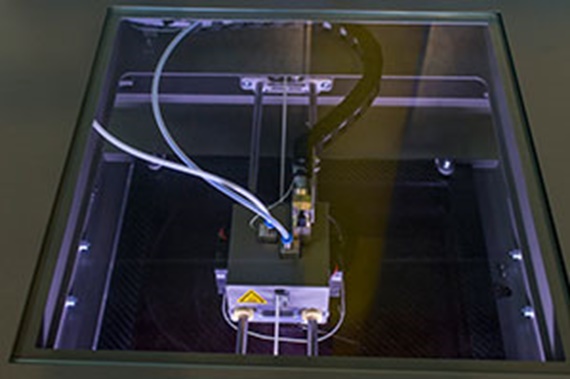

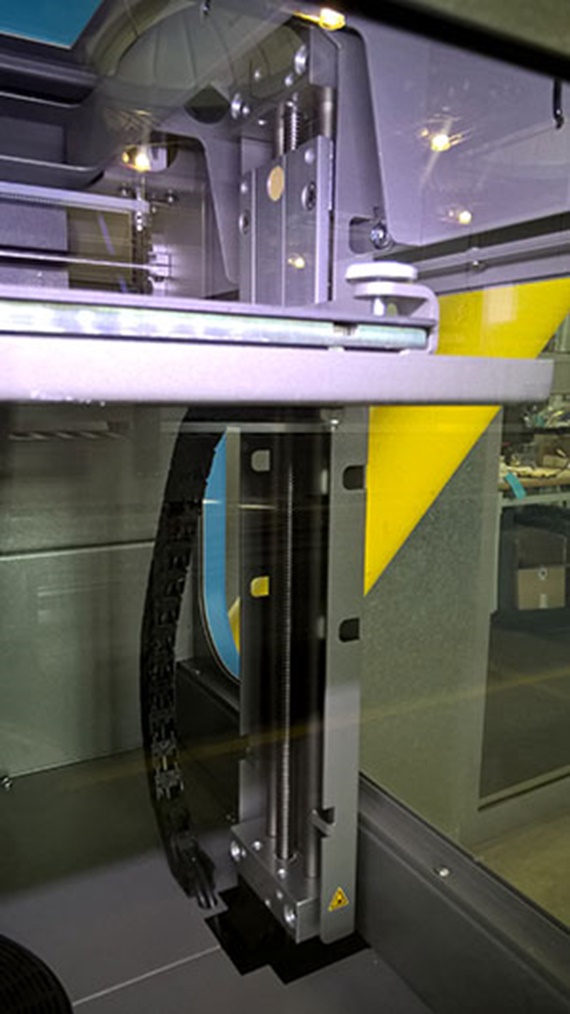

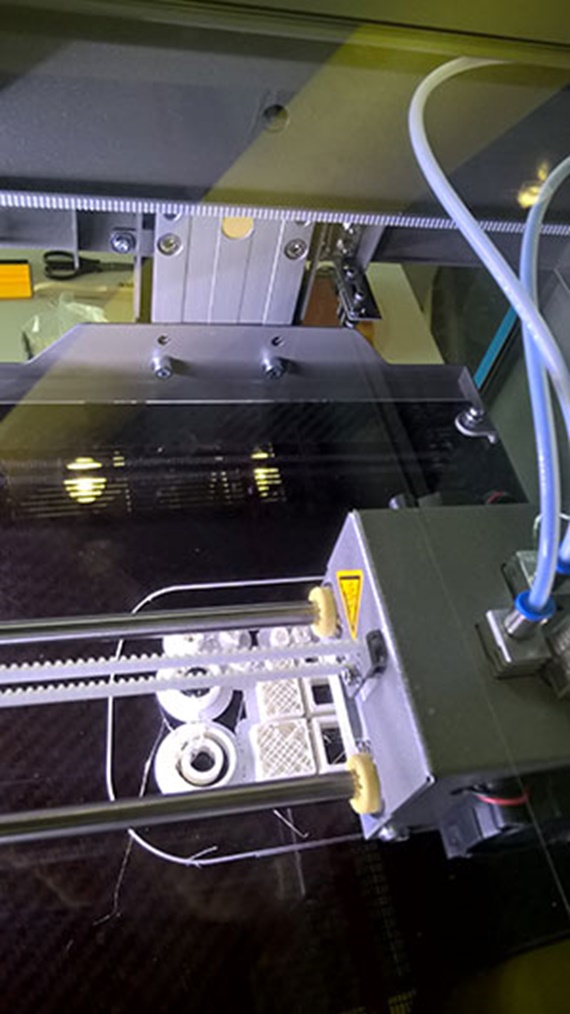

In the computer-controlled printing process, our plastic energy chains prove themselves in the safe guidance of the connection cables. Due to their low installation height and tight bend radii, the micro chain series are exceptionally suitable for dynamic applications in any direction of movement for the compact designs of 3D printers. Like linear plain bearings, the micro chain series also have a very lightweight. The chainflex control and motor cables routed therein, which are specially designed for permanently moving applications, prevent cable failures and guarantee a long service life for the 3D printer. Combined with motorised drylin linear axes, which include motor flanges, couplings and drylin E-stepper and DC motors, we can provide a completely ready-to-install operating unit from a single source.3D printer with lubrication and maintenance-free plain bearings

In addition to quiet operation, the quality of the objects produced is important for professional use. For example, lubricants can contaminate the raw material or printed product. Our plain bearings made of high-performance polymers completely dispense with lubrication due to integrated solid lubricants. There is therefore no risk of contamination. Dry operation also makes 3D printers maintenance-free and increases dependability. When it comes to moving parts in 3D printers, factors such as acceleration and positioning accuracy also play a role in order to be able to reproduce the product faithfully in detail on the basis of CAD models. The smooth-running drylin linear plain bearings and lead screw drives can be used for both slow and high accelerations, regardless of the travel.