Abrasion-optimised high-speed glide bar

5 times more durable than conventional glide bars

In the case of very fast gliding applications, the glide bars in the super aluminium troughs have been a potential weak point. They wear faster than the more abrasion-resistant chains. For these applications, an abrasion-optimised, injection moulded glide bar has now been developed. This is much more durable for the same price and will be used in future in all matching trough sizes.Submit an enquiry now

Tech up

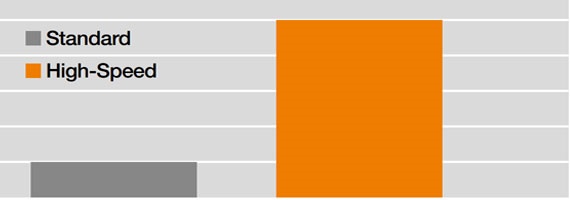

- Five times the abrasion resistance thanks to tribologically optimised material. High-speed compared to conventional glide bars

- For very fast gliding applications

- Short individual parts 500mm, easier handling

- New sizes available for many Aluminium SuperTroughs

Cost down

- More durable at the same price

- Significantly lower maintenance

- Assembly significantly easier due to 0.5m instead of 2m length

- Reduce construction effort with freely accessible configurator for CAD troughs

- Predictive maintenance – optional additional isense module

Proof

- High-speed glide bar abrasion tests Abrasion tests comparing the high-speed glide bar with the conventional glide bar were carried out in the igus® laboratory

Sustainability

- 50% weight reduction by switching from extrusion to injection moulding

- Have your energy chain recycled as part of the igus "chainge recycling programme" at the end of its life cycle. Irrespective of the manufacturer. You can receive a chainge recycling programme voucher

- igus supports the circular economy of plastics and is investing in chemical recycling. Learn more about this topic at: Chemical recycling

Technical details

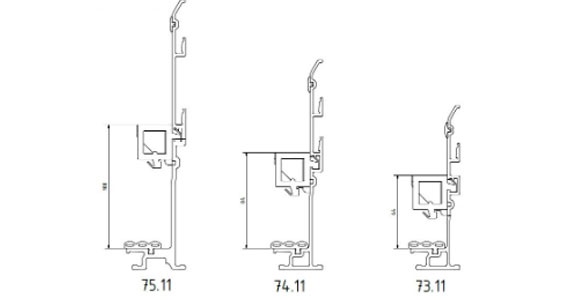

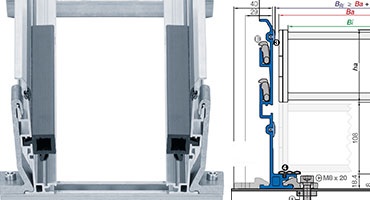

The GB.31.500 glide bar has a load-bearing surface of 31mm. It fits on 973.31SL, 974.31.SL, and 975.31.SL troughs and can thus be used with outer chain heights of 64mm, 84mm, and 108mm. It is simply clipped into the aluminium SuperTrough.

| Part No. | Aluminium SuperTrough |

|---|---|

| GB.31.500** | 973.31.SLH |

| GB.31.500** | 974.31.SLH |

| GB.31.500** | 975.31.SLH |

**Available from stock

Submit an enquiry now

Tested high-speed glide bar wear resistance

Comparison tests of real customer applications have shown that, for highly dynamic applications, the new GB.31.500 glide bars exhibit wear that is lower by more than a factor of five.This reduces glide bar maintenance costs to a minimum. Only when the energy chain has reached its wear limit does the glide bar require inspection. The new glide bar has no direct influence on the service life of the e-chain® itself.

Assembly instructions of high-speed glide bar

You might also be interested in this

Sensor for glide bar wear in troughs

Optional isense EC. T the sensor for glide bar wear monitoring in the guide trough.Sensors for smart energy chains and cables

Guide troughs

Guide troughs are used for long travels. They facilitate smooth, low-friction operation of e-chains® and e-tubes.About the guide troughs

Energy chains

Very different installation spaces and environments. Large product selection – find the right solution at once. With a 36-month guarantee.Go to energy chains