We take the difficulty out of even the most complex energy supply systems

We do all our engineering project planning in-house, testing everything carefully in the world's largest test laboratory for energy supply systems. Our global engineering and assembly network enables us to control projects all over the world and deliver, install, test and maintain our systems at short notice.

Scroll down to review our history in project highlights:

Scroll down to review our history in project highlights:

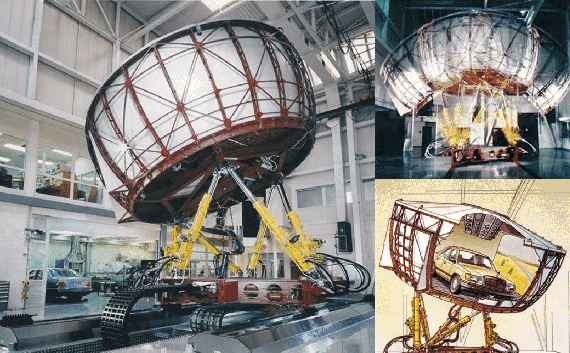

1992

First major project: driving simulator

At the time, the driving simulator was unmatched in its speed and acceleration.

1993

Offshore skidding application

In rig skidding applications, a harsh environment and high fill weights create tough conditions. The application was implemented successfully with an E4-series plastic energy chain. Advantages over steel chains:

- Corrosion and UV-resistant

- Cable and hose-friendly due to plastic interior separation system

- Weighs up to 70 % less than steel chains

- Modular design, easy to modify

- Seawater-resistant and offshore-capable

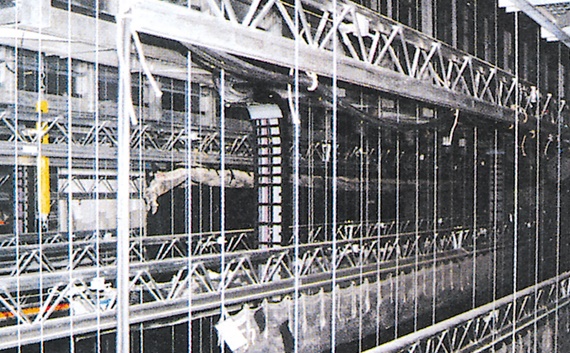

1995

Composting plant

Reliable energy supply systems at extremely high humidity: a customised heavy-duty guide trough with 6 m support distance, adapted to the building supports, was installed for use in a composting plant. It guides an e-chain (5050CR.40.300.S10.0.E) on 186m and at 0.17m/s and includes chainflex cables and hoses.

1996

RTG retrofit in the UK

The rubber tyred gantry had previously been equipped with festooning, a so-called cable-trailing system. Our pilot project with the 5050.35.250.0 energy chain, including chainflex cables and a stainless steel guide trough, was successful: today, more than 3,500 such systems are in use.

1997

Ship unloaders in Canada

Two ship unloaders were equipped with the 4040CR.15.250.0 energy chain in a galvanised project guide trough, including housing. The chain moves along a 151.5m travel at 5m/s – a speed unmatched at the time.

1998

Royal Opera London

Zig-zag solution for stage technology: on a travel of 30 m, the London Royal Opera's crossbeam was fitted with an e-chain with a compact deposit basket into which the chain folded itself quietly in a zig-zag movement.

1999

Rotation module for a telescope in Hawaii

A rotation module for Hawaii's Gemini Observatory at 4200m on the Mauna Kea volcano. The special challenges for this project were seismic safety and resistance to UV and ozone.

Rotating application of 540°

Equipment: azimuth with e-chain 640.600/600.400/1800.0, mirror with e-chain 5050.30.150/1825.0 can be rotated another 90°.

The original igus e-chains we delivered are still being used.

2003

Ship unloader in Malaysia

Three different e-chains ensure that the ship unloader has a safe energy supply system:

For the 441 m travel, the e-chain 5050CR.28.300.0 replaced the motor cable drum that had been in use. In the trolley drive, the 5050CR.21/21/21.250.S10.0.E e-chain moved along a 90.5 m travel at 3.16 m/s. The driver's cab was equipped with an e-chain 4040C.25.150.0 on a travel of 70.8 m.

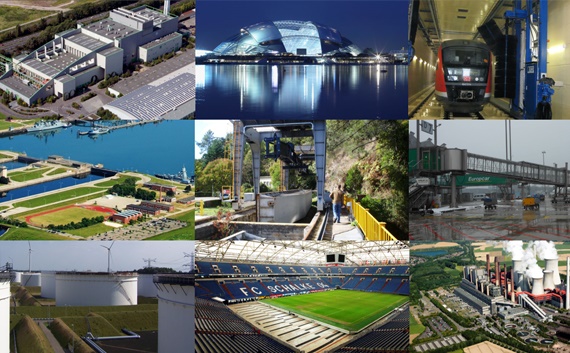

2003-2007

Project business picks up

Waste incineration plants, moving stadium roofs and playing fields, train washing systems, sea locks, dams, passenger boarding bridges, oil tanks, power plants ...Successful references in a number of industries documented our solution competence and spurred us on to new achievements.

2007

World record: longest travel – 615m

In the Czech lignite plant at Tušimice, we installed the longest plastic energy chain in the world – with a travel of 615m. Sometimes it is in 24/7 continuous operation; sometimes it does not move for a month. The chain manages these conditions without any problems – only a few plastic crossbars have been replaced. The chain used is the 5050RHD. The links have rollers that greatly lower the coefficient of friction and reduce the drive energy required to move the energy chain system by up to 57%.

More about this application

2009

Chain carousel in Vienna

You are probably familiar with the Ferris wheel in Vienna's Prater park. Another attraction is the chain carousel, which is 112 m high, making it the largest in the world. The energy supply system with its 80 m stroke uses an e-chain E4.56 with a chainflex cable package and a vertical flizz system. Speed: 2.7 m/s.

2010

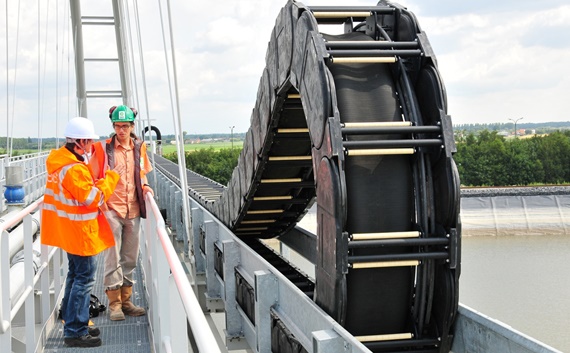

Largest e-chain in the world (Belgium)

The largest plastic energy chain in the world, the E4.350R, was used in the Amoras project in Belgium. The sludge treatment plant has an e-chain with a travel of 137m. It carries chainflex cables and a 300mm thick hose which , when filled with sludge and sediment, weighs around 100kg/m. In addition to the energy supply system, a corrosion-resistant guide trough made of aluminium and the iSense EC. P diagnostic tool was installed. The tool measures the push/pull forces acting on the chain and compensates for them with a calculated specification.

More about this application

2010

Bucket wheel excavator

A 360° rotating energy supply was installed in place of a slip ring on a reclaimer from the 1960s and 1970s, an application that involves very tight spaces and extreme dirt accumulation. The e-chain installed was a 5050C.30/30.400/6850.0, including fibre optic cables and network technology, an igus guide trough, and "floating islands" that ensure reliable guidance even with vibrations and skewed positions.

2012

Offshore: 900° rotation module

In the leg-encircling crane of a wind power installation vessel, we installed a 900° multi-rotation module (MRM). It allows reliable guidance of fibre optic and other data cables for such purposes as controlling the cameras on the crane. The complete system was designed and assembled according to the customer's requirements and accepted during the test drive.

2014

Shore power connection for the LNG Power Barge

To connect an LNG barge with the quay, we developed the igus shore power gangway. It is used to transfer personnel from the barge to the quay. It also contains an igus energy supply system that uses four medium-voltage cables with connectors that can be plugged into large power supply boxes on the quay. The system also compensates for the constant movements of the barge and can deal with swells and tidal fluctuations of up to 8 m.

2015

Demolition of an offshore drilling rig

To demolish an offshore drilling platform, the necessary cutting equipment, including camera monitoring , was submerged to a depth of 50m along the platform's support legs with the e-spool power, an igus cable drum without a slip ring. This allowed the facility to be demolished and prepared for transport.

2016

Largest rotary module

We used what is currently the largest rotary module for the the rotary winches of the riser pull-in system in an FPSO mooring turret. Maximum rotation angle: 380°.

2017

1,000 STS cranes equipped with e-chains

In 2017, we equipped the 1,000th STS (ship-to-shore) crane with an igus e-chain system, demonstrating that the trend towards lightweight, durable components is now state-of-the-art all over the world. In the vast majority of cases, rolling energy chains are used for long travels, increasing component service life, reducing drive power and greatly reducing noise.

2019

e-loop for hanging applications

We developed the modular e-loop energy chain for reliable cable guidance in hanging applications in the oil, gas and offshore industries and in construction machinery, shore power and wind turbines. It ensures a defined cable bend radius and withstands vibrations and shocks. In top-drive systems, the e-loop serves as an alternative to service loops, which break off in high winds and in which cables can break due to insufficient guidance.

2020

High-speed RBR

In the Italiana S. p.A. automatic lathe, a drum with six lead screws moves the workpieces to the relevant tools very precisely and in just 0.65 seconds. For the lead screws to return to the starting position, the drum has to reverse 300°. The unit, which weighs over three metric tons, needs only one second for this. A unique igus energy supply system that rotates with the drum and allows the linear lead screw drums' movements – with eight e-chains, 64 cables, and 73 hoses. For the application, Gildemeister Italiana won the 2020 Golden Vector.