Machine Heat Recovery System - the igus heating concept with waste heat

We have been using 100% green electricity at our production site in Cologne since 2021. By replacing old injection moulding machines with new ones that are 40% more energy efficient, we've reduced electricity consumption by 11% in relation to increased production hours. We use gas to heat our production and office buildings. We switched to climate-neutral gas in 2021, but we were concerned that we were using resources for heating when enough heat was already being generated, namely at the injection moulding machines. And, as of 2023, we have around 800 of these, distributed over several buildings. How do we manage to use the waste heat? That's what a team of igus engineers asked themselves and started trying it out. The result: the concept for heating without gas by using the waste heat from the machines. The plan: to no longer heat any buildings at the company's Cologne site with gas and to make the concept freely available to engineers and mechanical engineers, i.e. to industry.

The idea

During the injection moulding process, the hydraulic motors of the injection moulding machines get heated. To prevent them from overheating, the motors are cooled with cooling water. The cooling water is provided by cooling towers, from which the cold water is pumped to the machines. There, the cooling water absorbs the waste heat from the motors and is heated and fed to the fan heater. A fan located on the fan heater heats the drawn-in air and thus heats the hall. At the same time, the heated cooling water cools down during this process and is pumped back to the cooling tower and the process begins again.The system is variably adaptable and enables the assurance of constant temperatures even in particular production areas. It does not use the detour via a heat exchanger, which would lead to temperature losses. Additional heating of the water using compressors is also not necessary. Since heat is extracted from the hot water as it passes through the fan heater, the cooling requirement of the cooling tower also decreases, which in turn saves energy.

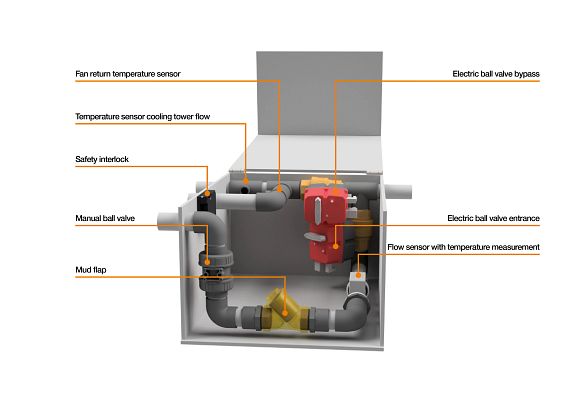

The control unit in detail

The device developed by our engineers sees to it that a fan heater within the production hall is supplied with maximum heat energy and at the same time prevents machines from being damaged by excessively high temperatures in the return flow.

The heated cooling water from the machines enters the device via the inlet on the right-hand side of the device. Water flows through the electrically adjustable ball valve to a flow meter that measures the temperature. The temperature of the cooling water in this area must be at least the same as the desired room temperature so that the water can be routed to the fan heater via the dirt trap and the manual ball valve. Otherwise, the electric ball valve blocks the passage and opens the bypass via the electric ball valve. The water cools down as it passes through the fan heater. This temperature is recorded by the temperature sensor. The heat output of the fan can be calculated from the temperature difference and the flow, which is shown on the display. Since there is hot water inside the pipes, the device can be locked to avoid burns. Since there is always dirt in the return pipelines, a dirt trap is used to filter coarse particles. In order to replace this from time to time, the ball valve can be turned over manually. This will prevent any water from flowing back down from the fan heater and flooding the unit.

What happens next

The time between idea and implementation sometimes goes by in a flash, as was the case with our "hall heating" project. We performed tests and tried things out, and suddenly there was a breakthrough: we were working in T-shirts even though the gas was turned off. As of April 2023, we are in the process of adapting our concept so that we can offer it for free. We will talk about it at the 2023 Hannover Messe. If you would like to find out when and how you can benefit from our waste heat concept, subscribe to our newsletter or visit this page regularly.

Registration for the newsletter

More about igus

Openly & flexible — The igus factory

Our heating system is not the only thing that is special. Our building structure itself is, too. The architecture of our headquarters in Cologne follows the guiding principle that the customers are the sun situated at the centre of our actions. In the distance, sun-yellow pylons support the old and new factory buildings. They need no walls and can be flexibly redesigned and expanded.

Learn more now

Plastics and sustainability

Learn more about sustainability at igus

Going into the future with curiosity

Learn more about digitalization at igus

Virtual tour of the igus factory

Start the virtual tour now