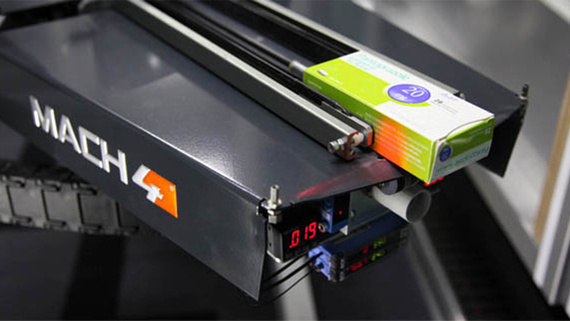

Energy chains in a picking system with 20,000 movements a day

Durable cable guides and chainflex cables for demanding medicine handling

Functionally reliable, durable, quiet, wear-resistant, space-saving: these are the requirements for energy chains used in the automatic medicine-picking systems of the company Omnicell GmbH (formerly known as Mach4 Automatisierungstechnik GmbH). Whether in a pharmacy, hospital or nursing home - the modular systems for quick storage and retrieval can be adapted to almost any space conditions on site. Here, fully harnessed readychain energy supply systems ensure the required long-term operational reliability.Profile

- What was needed: E2/000 series energy chains and servo, bus, control and pneumatic cables from the chainflex product range, supplied as fully harnessed readychain systems

- Requirements: durable, functionally reliable, low-abrasion, space-saving, quiet energy supply

- Industry: mechanical engineering

- Success for the customer: installation time is reduced and necessary machine adaptations can be carried out easily

See all products for vending machinery

Problem

At the moment, there are almost 21,000 chemists in Germany. Demographic change is also making itself noticeable here. Their number is expected to level off at around 17,000 to 18,000 in the next few years. An individual chemist's shop has to be able to do more in the space it has available. In addition, the population is getting older. In this environment, automation plays an important role as layout and storage spaces vary considerably. The medicine handling systems must be both compact and modular in order to enable a problem-free expansion and a reliable supply.This also applies to the customised picking systems of Omnicell GmbH. The provider in the field of pharmaceutical logistics needed a solution for the energy supply of their systems, where travels of up to 17m can coincide with speeds of up to 4m/s and an acceleration of up to 2.5m/s2. The travel speeds and accelerations are associated with a high continuous load. In a classic chemist's shop, the daily storage and retrieval operations amount to around 300; in hospitals, this can increase to up to 20,000 trips. In individual systems, between 9,000 and 60,000 packages can be stored. Depending on the composition of the individual system, between 150 and 1,200 packages can be delivered, and between 300 and 8,700 retrieved per hour.

Solution

From day one, high-performance energy supply systems and cables from our energy chain range are used in the Omnicell systems. Specifically, e-chains from the E2/000 series are used, which can be opened from the inside and the outside, and are characterised by easy and versatile assembly.Usually, between two and five completely harnessed energy chain systems are used, which are called "readychains". They combine robustness and abrasion resistance and operate quietly with low vibration. Moreover, they need little installation space due to the small bend radii. This is very important in order to be able to use the space available in a medicine storage space most effectively. Because of the very small chain link pitch and the resulting reduced polygon effect, there are hardly any vibrations or shocks. This means that the chemist's customers barely notice the background picking processes that provide the medicine as if by magic.

They contribute to the good technical data of the systems while minimising the installation effort.

But we also provide the cables ourselves. At Omnicell, for example, functionally reliable servo, bus, control and pneumatic cables from the chainflex range ensure the required performance data for fast picking of the medication packaging.

Calculated online and delivered in 24 hours

The component supplier and the medium-sized mechanical engineering company work closely together. A few years ago, an order-picking system was designed that can drive 90° around the corner. "The solution was found quickly", the CEO looks back. "While the chain is on the floor in the standard machines, it stands on the cam-controlled automatic machines and ensures a reliable energy supply to the various control and drive units." In addition, the delivery capability is right. "The delivery of a system has never been delayed because of bottlenecks", confirms Malajka. This aspect is very important to igus, so all products including service life can be calculated and ordered online and delivered from 24 hours.Overview of ready-to-install energy chain systems

motion - magazine for energy chain systems®

Improve the performance of your machine ... Cost down.

In this igus® magazine you will find numerous possibilities and application examples of how you can bring your tech up and/or cost down with ready-to-install energy chain systems.Order your personal copy here