Cable guide guidelok swing GLO.S

For jib cranes with travels of up to 10 metres

Jib cranes are an indispensable part of industry. They transport workpieces of all kinds - to loading ramps, processing machines and assembly stations. However, failures can always occur - for example, when energy and data cables that hang down are damaged by a forklift during workpiece unloading. Consequences are downtime, unplanned repair costs and even production delays. To increase system safety and productivity, igus has developed energy supply system guidelok swing GLO.S. With the guidelok swing GLO.S, energy and data cables no longer hang in the air, but move directly in the jib crane's girder contour.Buy guidelok swing GLO.S now

Tech up

- Very slim, space-saving design

- Long service life due to safely guided cables

- No cable loops hanging down

- More space between crane girder and energy chain (8-19mm), allows larger bend radii

Cost down

- Cost-effective – without the need for any guide troughs

- Save installation time

Proof

- Tests in the igus laboratory and in the factory

- In use at the igus factory

Sustainability

- Recycle previously installed energy chains for free through the igus® chainge recycling program. No matter what manufacturer.

This is how the guidelok swing GLO.S works

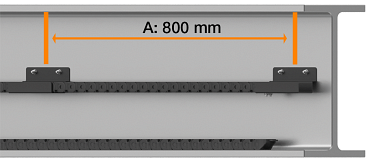

The lower run rests on the T-beam flange and is connected to the trolley. The upper run is held above the trolley by the guidelok swing's rocker elements. Rockers are screwed to the crossbar of the T-beam every 800 millimetres. When the upper run passes, the chain radius pushes the rocker flaps up and engages. In the opposite movement, the flaps open like a trapdoor and release the upper run again. The advantage: low wear and a long service life, as the upper and lower runs never touch.

Technical data

Position of the holes

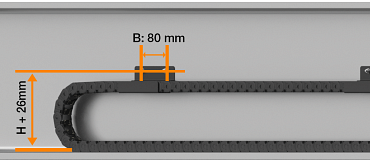

B = horizontal distance: 80mmHeight = H + 26mm

Diameter = 8.5mm

Travel and support gap

Travel: 3 to 10mA = Support gap: 800mm

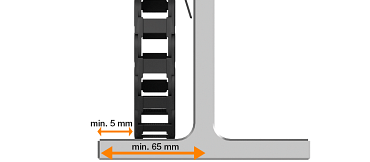

Minimum width of load-bearing surface

Minimum width of load-bearing surface for lower run: 65mmReal-world examplesSEW-Eurodrive is the first to use the new guide system. The German drive technology manufacturer has equipped an indoor crane with the guidelok swing at its plant in Gauteng, South Africa. The crane moves components for chemical cleaning with a high-pressure cleaner. The user has opted for the guidelok swing GLO.S. By using the guidelok swing GLO.S, it was possible to reduce the risk of accidents while increasing the crane's reliability. Discover guidelok swing GLO.S in the shop now Discover guidelok swing GLO.S in the shop now |

Test laboratory: GLO.S in use in the igus factory

Suitable energy chains for the guidelok swing GLO.S

Series E2.21

Inner height hi: 21mmInner width Bi: 50 to 68mm

Bend radius R: 35 to 180mm

Pitch: 33.3mm

To the e-chain E2.21 shop

1400 series

Inner height hi: 21mmInner widths Bi: 15 to 125mm

Bend radii R: 35 to 180mm

Pitch: 33.3mm

To the e-chain 1400 shop

You might also be interested in

Energy chains shop

Buy energy chains now