Ground support equipment – lubrication-free thanks to motion plastics

When aircraft are on the ground, everything has to move quickly. To manage turnover as quickly as possible, a number of special vehicles have been developed: ground support equipment (GSE).

This equipment handles a variety of tasks – fuelling, unloading cargo, de-icing, boarding – simultaneously. Challenges, especially for the components, include flexibility (each aircraft is of a different size, so the GSE must be able to change its height) and absolute reliability. Whether the airport is enjoying sunshine or caught in a rainstorm or snowstorm, the GSE must function reliably. Any failure is expensive.

All over the world, customers rely on motion plastics, since they are maintenance-free, resistant to corrosion and chemicals and absolutely reliable, and their service life is predictable.

This equipment handles a variety of tasks – fuelling, unloading cargo, de-icing, boarding – simultaneously. Challenges, especially for the components, include flexibility (each aircraft is of a different size, so the GSE must be able to change its height) and absolute reliability. Whether the airport is enjoying sunshine or caught in a rainstorm or snowstorm, the GSE must function reliably. Any failure is expensive.

All over the world, customers rely on motion plastics, since they are maintenance-free, resistant to corrosion and chemicals and absolutely reliable, and their service life is predictable.

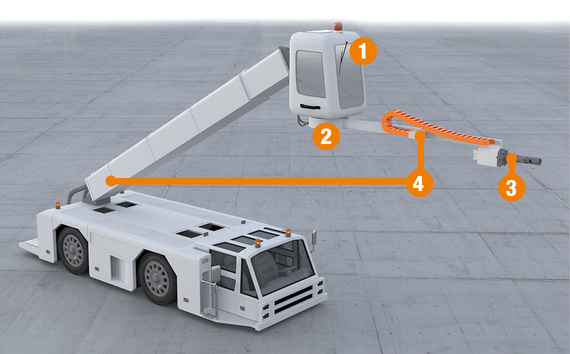

De-icing vehicles | De-icing

To ensure aerodynamics and safety during flight, aircraft must be completely free of interfering objects. This includes ice and snow in cold seasons. This is a complex task that is demanding for humans and machines and must be completed under time pressure.

Our energy chains, cables and bearing technology have been tested under extreme conditions and are eminently suited to use in telescopic arms, cabin rotation or spray nozzles. Certain iglidur materials are also resistant to media such as glycol, formic acid, kerosene and Skydrol.

Our energy chains, cables and bearing technology have been tested under extreme conditions and are eminently suited to use in telescopic arms, cabin rotation or spray nozzles. Certain iglidur materials are also resistant to media such as glycol, formic acid, kerosene and Skydrol.

2. Cabin rotation

3. Nozzle settings

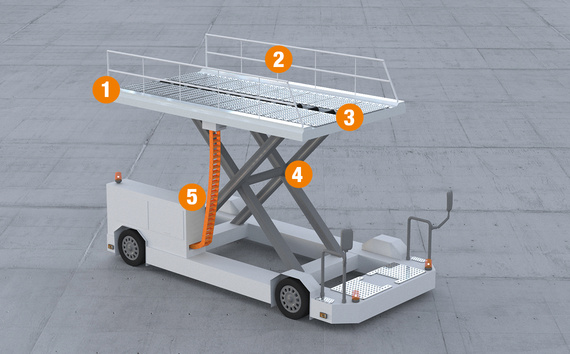

Cargo lifts | Cargo loaders

Cargo loaders are used in airports to load luggage or large containers into aircraft. They must be able to handle heavy loads and tough conditions and have adjustable heights.

e-chain and chainflex cables are ideal for guiding cables in the height-adjustment mechanism. dry-tech plain bearings, thrust washers and rollers can be used flexibly, completely without lubrication, even with loads of up to 200 MPa. That is why they are used in applications such as scissor lift tables and platforms.

e-chain and chainflex cables are ideal for guiding cables in the height-adjustment mechanism. dry-tech plain bearings, thrust washers and rollers can be used flexibly, completely without lubrication, even with loads of up to 200 MPa. That is why they are used in applications such as scissor lift tables and platforms.

1. Folding mechanism for railings

2. Railing extension mechanism

4. Scissor lift

5. Vertical movement

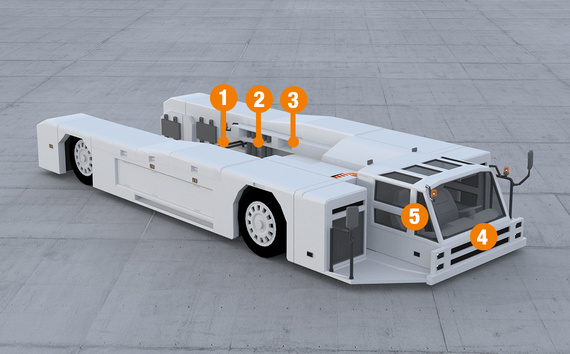

Aircraft tractors | Pushers

Aircraft tractors, also called "pushers" or "towbar tractors", are true behemoths. They are used to move aircraft on runways or in maintenance hangars. Some models clamp the front wheel in a mechanism and lift the aircraft.

iglidur heavy-duty plain bearings are used in this clamping mechanism, energy chains are used to guide cables and hoses, and PRT slewing rings ensure the necessary seat rotation in the driver's cabin.

iglidur heavy-duty plain bearings are used in this clamping mechanism, energy chains are used to guide cables and hoses, and PRT slewing rings ensure the necessary seat rotation in the driver's cabin.

1. Doors, hinges and flaps

2. Clamping device

3. Clamping device

5. Cabin rotation

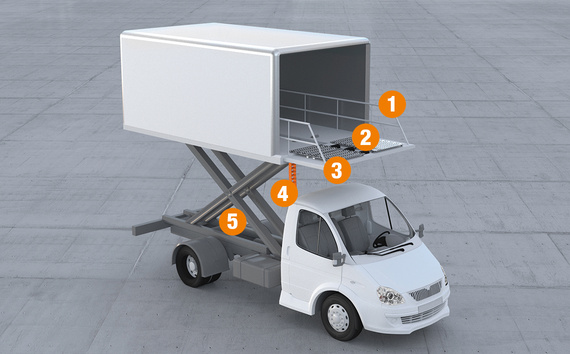

Catering trucks

Catering trucks are used to remove empty service trolleys from the aircraft and replace them with full ones. The last few metres between truck and aircraft are usually managed with a telescoping platform.

motion plastics offer a number of applications here: e-chains for cable guidance in height adjustment and drylin linear bearings and iglidur plain bearings in the platform. motion plastics are useful here because they require no lubrication, have high edge loads, and are resistant to chemicals such as Skydrol, formic acid and glycols.

motion plastics offer a number of applications here: e-chains for cable guidance in height adjustment and drylin linear bearings and iglidur plain bearings in the platform. motion plastics are useful here because they require no lubrication, have high edge loads, and are resistant to chemicals such as Skydrol, formic acid and glycols.

1. Railing extension mechanism

3. Telescoping platform

4. Vertical movement

5. Scissor lift

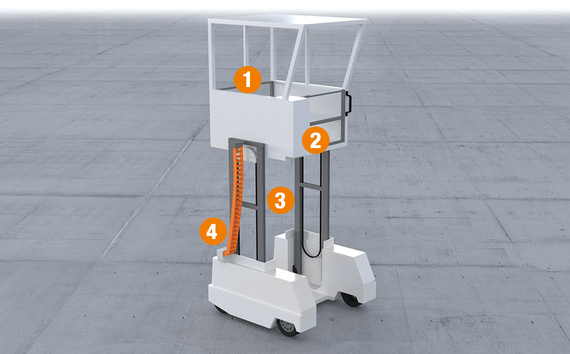

Ambulifts

Ambulifts are used to allow individuals with physical limitations to board the aircraft safely and conveniently. They require a number of movements, both on the front side, where passengers enter the ambulift, and the rear side, where they board the aircraft. motion plastics allow these movements to be entirely lubrication-free and automated.

1. Doors, hinges and flaps

2. Telescoping platform

3. Vertical platform adjustment

4. Vertical movement

Selected application reports by our customers

Aircraft tanker

This tanker is used to fuel aircraft at airports all over the world. To fuel different types of aircraft, the crane boom must be as flexible as possible. e-chains and chainflex cables that work in very tight installation spaces are used here.

Go to user report

Aircraft de-icing and washing system

This all-in-one concept de-ices and washes aircraft in a fully automated procedure, saving airport carriers a great deal of time and money. Energy chains provide safe, reliable cable guidance under tough environmental conditions such as extreme cold, moisture and chemical use.

Go to user report

Aircraft handling

Quickloading, an engineering office, develops solutions to facilitate and accelerate aircraft handling. E.g. in an aircraft de-icer in Siberia or a

ventilation and de-aeration system for aircraft interiors, iglidur plain bearings are used continuously in outdoor applications in extreme heat or cold and with acidic de-icing agents.

ventilation and de-aeration system for aircraft interiors, iglidur plain bearings are used continuously in outdoor applications in extreme heat or cold and with acidic de-icing agents.

Go to user report