Large machine tools

Energy chains, cables, and bearing technology for gantry machining centres

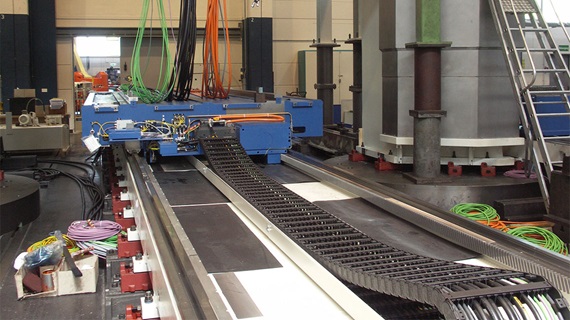

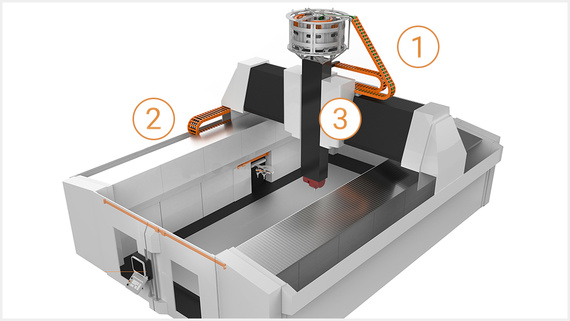

In tool- and mould-making, gantry machine tools allow the machining of large components. This places enormous demands on cable guidance systems, which often reach travels of more than ten metres and must safely move the heavy weights of the various energy and data cables and hydraulic lines.

In order to reliably handle this task even in three-shift operation, seven days a week, we are constantly refining our energy chain systems for machine tools. Maximum system and planning reliability in day-to-day operations are always the focus here.

In order to reliably handle this task even in three-shift operation, seven days a week, we are constantly refining our energy chain systems for machine tools. Maximum system and planning reliability in day-to-day operations are always the focus here.

Tech up and Cost down: our top products for large machine tools

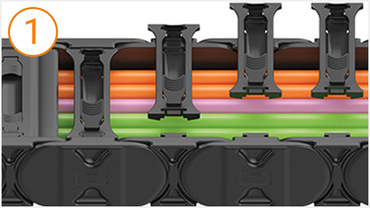

E4Q energy chain system

- Highly robust and modular

- Optional noise dampeners for quieter operation

- Reduction in material leads to lighter weight

Learn more about the energy chain system

Horizontal upper run guide

- Allows long energy chain travels

- Chips cannot settle between the gliding surfaces

Learn more about the guidelok guidance system

Intelligent connector system

- Strain relief in the housing

- Space-saving due to flat housing

- Connectors adapted to energy chain geometry

Find out more about Module Connect

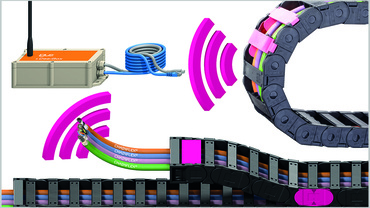

Predictive maintenance

- Intelligent software and sensor technology on the e-chain

- Possible maintenance needs reported before failure occurs

Find out more about smart plastics

Plain bearings for tool changers

- Completely lubrication and maintenance-free plain bearings

- Made of wear-optimised iglidur material

- Calculate service life with online tools

Find out more about iglidur plain bearings

The best price-CABLE ratio

- Four-year guarantee

- Use the price check to always find the cable that costs least and is guaranteed to work

Learn more about chainflex cables

Large machine tool application stories: The right solution for any challenge.

Especially long travels

Reliability, rigidity, and efficiency: For its horizontal lathe, Gurutzpe was looking for an energy and signal supply solution that could meet these requirements. Today, two guidelok energy chains running in opposite directions are used over a length of 13.5m.

Learn more about this application here

High availability under continuous load

Waldrich Coburg's customers often use the large machine tools for 20-30 years or longer and often require availability of at least 95%. Our robust cables and connectors are among the elements in demand here.

Learn more about this application here

Quick, simple assembly

In its gantry machining centres, Hartfort, a tool manufacturer, uses pre-assembled readychain energy chains. The advantage: Work steps can be eliminated, reducing assembly time for this application from several weeks to just half a day.

Learn more about this application here

Heavy cable weights and long travels

In this large-scale machine tool, an especially large number of cables and hoses were required to supply the various spindles with energy, media, and data. A guidelok energy chain system carries the heavy weight over a travel of 13 metres.

Learn more about this application here

Vertical travels

In this milling machine for bicyles, no less than 15 igus energy chains were installed in all track axes, the stroke cabin, and the tool changer. A plastic energy chain also ensures safe cable guidance on a 7,100mm vertical travel.

Learn more about this application here

Tested for real-world applications in the industry's largest test laboratory

Further information

Magazine for machine tools

Important information about our products and servicesOrder now!

e-chains configurator

Configure your desired product online and view price, service life, and delivery timeStart now

Magazine for energy chain systems

Information about our energy chains and use casesOrder now!

igus blogs

Plastic chains despite 850°C chips? Sensors in e-chains? Important topics dealt with clearly.Learn more