Energy supply systems for the production of electric and hydrogen drives

Energy safely guided – in all directions and with small bend radii

Welding and gluing robots are a main component of the automated production of electric and hydrogen drives. High manoeuvrability and speeds characterise these precise machines. To keep up, each sub-component must fulfil certain requirements. Energy chains mounted on the robot's exterior should be flexible, while protecting cables and material hoses reliably, even when their bend radii are small. The energy chains should also be easy to open so that cables and media hoses can be replaced quickly.Success stories

Energy safely guided in high-speed sheet feeder

By using linear motor technology, Strothmann GmbH has set new standards in terms of performance and speed. The energy supply with the E6 is perfectly tailored to the high speed and acceleration values and allows a continuous, reliable supply even over longer distances.

More about this application

Suitable products

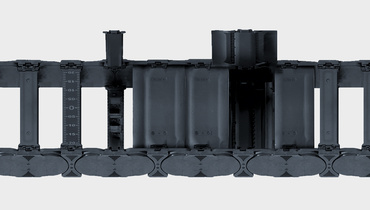

e-chain E4.38L

- Openable from both sides for short assembly time

- Attachment from any side with KMA mounting brackets

- Chip protection due to tightly closing lids and bottoms

More information about the E4.38L

e-chain triflex R TRCF.85

- Safe energy supply for multi-axis 3D movements with small bend radii

- TRCF – enclosed design with snap lock mechanism

Harnessed dress packs

Consisting of a triflex R e-chain, completely filled with chainflex cables and hoses for the supply of energy, data and media.More information about the dress packs

Cables for motion

- Developed for maximum load

- Torsion-resistant cables

- Suitable for very tight bend radii

- Four-year chainflex guarantee

Find out more about chainflex

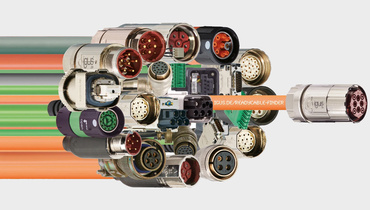

readycable

- 4,600 harnessed cables suitable for 24 manufacturer standards

- Find the most economical drive cable from 7 cable qualities, guaranteed to work

Learn more about readycable