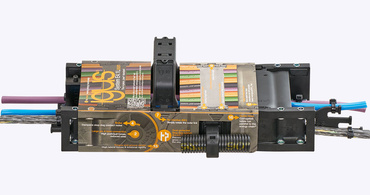

E4.1L system design principle

Save up to 80% of installation time with E4.1L

See how assembly time can be reduced and what features are offered with E4.1L e-chains® E4.1L makes filling quick and easy. E4.1L makes retrofitting cables much easier: individual cables can be taken out and new ones inserted, without removing cables located above them.Learn more now

Go to shop

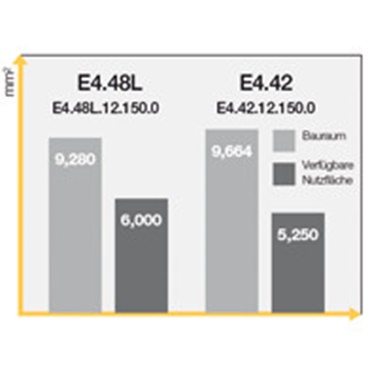

1. Optimised ratio of inner/outer dimensions

More effective space

An optimised ratio of inner and outer dimensions can be achieved by means of narrower outer links and the geometry of the crossbars. This creates more usable space in the energy chain.

Effective space tested

Given the same installation space, several cables and hoses can be guided in the E4.1L.2. Pivotable & removable crossbars

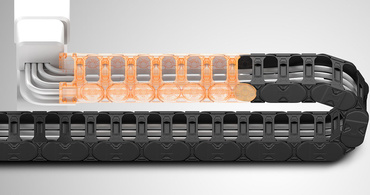

Open, fill and close in seconds

Simple and fast

Thanks to their design, the crossbars can not only be completely removed from the E4.1L, but can also be detached on one side. The crossbars remain attached to one side of the energy chain, cables can be inserted or removed and the energy chain can be closed quickly.

Breakage test in the igus laboratory

The crossbars can withstand high forces of up to 450N. Tested in experiment EW13-0043. Cable-friendly and flexible interior separation

For a longer service life due to a rounded base

Cable-friendly plastic crossbars

Smooth, cable-friendly and rounded contours ensure a long service life of the cable and hoses. With a few standardised parts, better and more cable-friendly interior separation is possible.

Wear tests

With the new rounded dividers, the wear of the cables could be halved.Test 3.748: Separator 301 compared to new version 45.1. Here, the combination of plastic and jacket material proves to be the best choice.

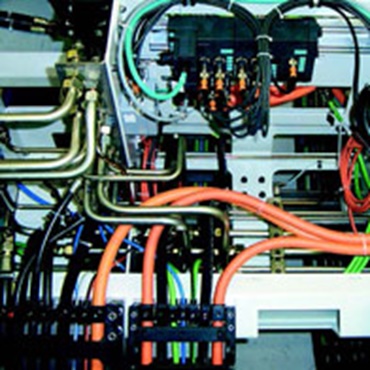

Plastic crossbars in use

In this application, rounded crossbars help to increase service life in plastics machining equipment.4. Noise brake

Dampens stop-dog and rolling noises

Brake

The principle is simple but highly effective. A wedge-shaped contour in the energy chain dampens the impact noise. Noise level from 33dB(A) possible, 44dB(A) measured with our E4 series. Many series certified by TÜV Rheinland.

Noise test

We test the energy chains in our own laboratory for noise emission. We also have many series inspected by the TÜV. Noise values of our energy chains, for example, are between 33db(A) and 46dB(A).Test 4.381: E4.32 with running noise below 44db(A) impact noise, at 1m/s

Even lower noise with dampening pads

If the unrolling noise has to be reduced even further, the optional dampening pads can help. They enable a reduction of up to 5 dB(A).5. Vertical, rectangular stops

For maximum force absorption and therefore a high degree of stability in the case of unsupported lengths

Double, rectangular stop-dog

More than two stop-dogs are not, or are hardly to be synchronised. Due to a rectangular geometry, the force distribution is much better than with a round stop(surface pressure formula, p=F/A). The complete E4.1L range has the double rectangular stop-dog. Max. fill weight unsupported up to 600kg/m possible. Max. unsupported lengths (FLB) 8.0m (+25% with the optional XXL material).

Fracture test

We test every energy supply system for compressive and breaking force using a Zwick testing machine. This allows us to be able to give reliable information on maximum fill weight and unsupported length. Test EW13-004

Automatic welding machine with upright E4.1L

The double rectangular stop-dogs and the undercut design of the energy chain ensure high lateral stability and optimum cable protection, even when the energy chain is stationary.6. Vertical stop-dogs and large pins

Better force distribution and thus absorbs higher push/pull forces and loads

Vertical stop-dog and large pin

Instead of absorbing the force centrally, by moving the stops, the force is guided through three points, namely the two stop-dogs and the large pin. This reduces the load on the individual elements, pins and stop-dogs to about 1/3. Pull/push forces up to 7,000N possible. Fill weights up to 600kg/m and more possible.

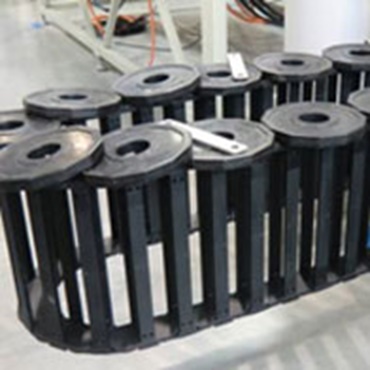

Endurance test lasting 96 hours - maximum unsupported lengths

The maximum load is tested over a period of 96hrs. The photo shows an E4.1 with the optional material "XXL", with which the maximum unsupported length can be increased by another +25% to approx. 8m.7. Large pin & bore connection

High push/pull forces and reduced wear due to tight tolerances.

Large pin/hole connection

Large pin/bore connections with tight tolerances provide high push and/or pull force absorption capability. Due to the tight tolerances, resulting in complete freedom from backlash, maximum accelerations can be achieved with little wear. Travels of over 600m possible. Accelerations of 10m/s² and more.

Tensile test with Zwick material testing machine

We test each energy supply system for tensile force. This enables us to obtain reliable information on the maximum possible travel and the possible acceleration values.Test 3.992: More than 30,000N tensile force possible

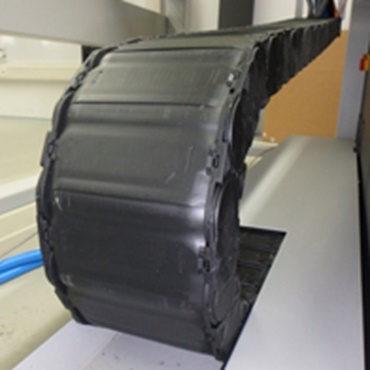

E4.1L in palletising machine

In this example, an E4.1L is being used in a palletising machine for drinks crates. Due to the rapid movements of the machine, it is especially important that the chain is designed for high speeds and stability.8. Inner/outer link principle

For a straight run, a high degree of parallelism and exceptional strength

Inner/outer link principle

Alternating inner and outer tabs interlock, which results in a straight run of the energy chain. This enables perfect mobility of the energy chain and increases the durability of the product.

Function test

The inner and outer link principle is tested on all E4.1L e-chains.

On site assembly over long distances

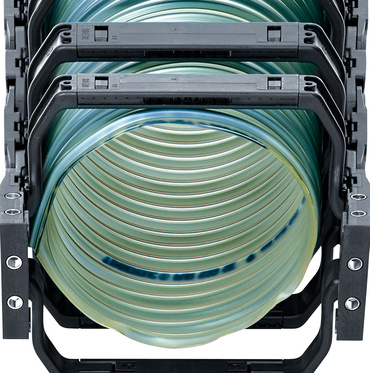

This energy chain is guided in a channel, which has minimal gaps on the left and right. This is made possible by the straight course of the E4.1L and avoids lateral wear of the energy chain.9. Undercut design

For a high degree of stability during lateral acceleration and for high torsional rigidity thanks to an "interlocking feature"

Undercut design

An "interlocking" of the chain links ensures a very high torsional stiffness of the energy chain and long unsupported lengths even in laterally rotated applications. Fill weights of 7.7kg/m on 2m unsupported.

Breakage test with Zwick material testing machine

We test each system for maximum load capacity to provide reliable service life data. This is incorporated into our online service life calculator.Test 4.099: 2m E4 e-chain with 7.7kg/m fill weight

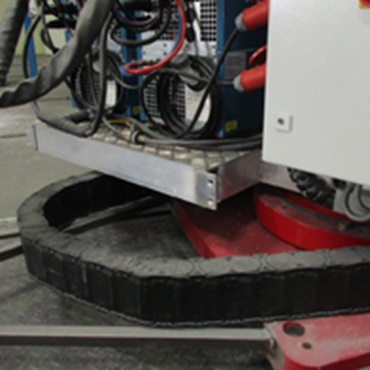

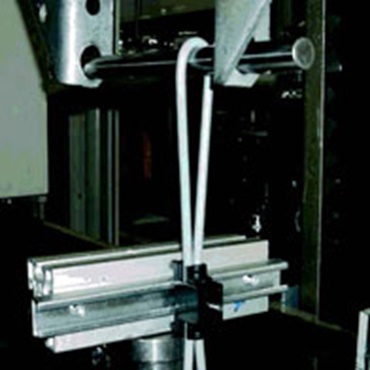

Sideways position in an automatic welding machine

An E4.1L e-tube in a sideways position in an automatic welding machine can be seen. It protects cables against flying sparks and, thanks to the undercut design, is also extremely stable for uses where it is in a sideways position.10. Few parts, made of one material

Quickly assembled, no varying material expansion

Few parts

Few parts made of one material that guarantee the smallest possible play, are particularly important for high acceleration. A uniform material is ideal when the material expands or shrinks due to temperature differences. Accelerations up to 784m/s², same materials.

Speed test

To meet the highest demands, speeds of up to 10m/s and more are regularly tested in the igus laboratory.

E4 in a crash test installation

Extremely high accelerations of up to 784 m/s² require an exactly tailored and clearance-free energy supply system. A few parts ensure this.Crash test facility

11. Wear pads

Long service life in spite of being used in a sideways position and having a long travel

Wear pads

The wear pads on the sides of the E4.1 ensures that this energy chain can withstand heavy use and has a long service life. Lateral wear pads ensure a long service life. This is an important characteristic, especially for side-mounted applications. 10,000km and more running performance guaranteed.

Length of travel tested

In endurance tests, the service life of the energy chain is tested in abrasion tests and with long travel distances. Every energy chain achieves at least 10,000 km running performance and often more.

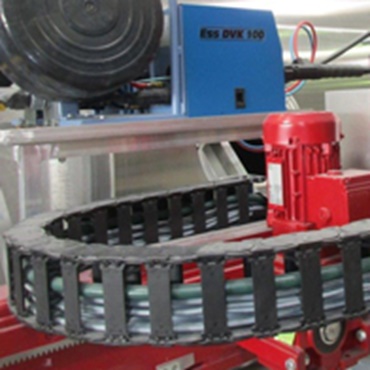

Circular reverse bend radius (RBR) application with side-mounted energy chains.

Due to the wear pads, large circle diameters with high filling weights are feasible. In this crane head, the laterally rotated energy chain performs a 400° rotation.12. Cable-friendly plastic crossbars

For an even longer service life of the cables due to the rounded design

Cable-friendly plastic crossbars

Smooth, cable-friendly inner contour and rounded crossbars ensure a long service life of cables and hoses. In tests, the combination of the Tribo-optimised plastic of the crossbars on the one hand, and the jacket material of the cables on the other, is found to result in the longest cable service life.

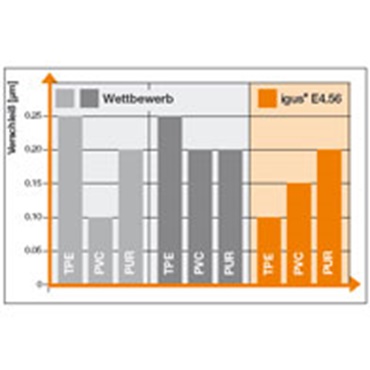

Test of plastic crossbars

Cable wear on plastic crossbars: Jacket made of a wide variety of materials show the best wear results with plastic crossbars. Moreover, compared to aluminium crossbars, they cannot be structurally deformed when force is applied from outside.

Coal excavator

Even in such rough applications, like here in a coal excavator, wear naturally plays a major role Among other things, hydraulic cables are guided in the energy chain and a failure becomes really expensive.13. Locking crossbars with scale markings

Easy pre-configuration with interior separation ensures secure retention even in the case of "laterally rolling applications".

Scale of the crossbars

Scalable crossbars are standard on all E4 models. This makes pre-configuration with interior separation segments easier and assembly time shorter. The locking separators can be located on the crossbar in 5mm steps and grip securely (approx. 25kg holding force) No spacers are required for side-mounted applications.

Cable wear

We test all chainflex cables for wear and service life through continuous operation in long term trials We also test customer-specific cables in order to be able to predict the service life of the system.

E4.1L hanging sideways

Cables safely guided in a side-mounted E4.1L rotating 90° The interaction of the energy chain material and the jacket material of the cables is a decisive factor in terms of service life.14. Large selection

Available in four sizes and many widths

Accessories and extras

Various extensions make the E4.1L system very flexible and are available from stock. For example, there are brackets for carrying hoses up to Ø 300mm or various noise-dampening options.

Extension link test

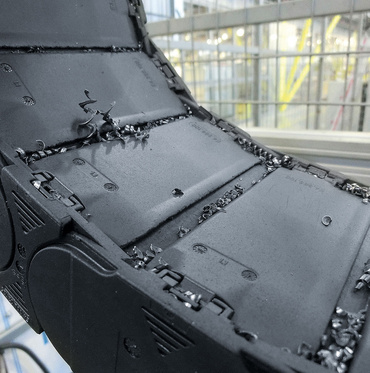

Due to the additional extension link, widths of up to 2000 mm are possible.15. Good protection against dirt and chips up to 850°C

For the protection of your cable

For the protection of your cable

Our energy tubes have been used successfully protecting against chips for almost 20 years. Dust, dirt, oil, aggressive environments, moisture, cold and heat do not affect the tough plastic energy supply systems. The optional HT material allows 850°C hot chips to simply bounce off.

The amount of chips that have burned into the material in relation to the temperature

In the test, 20g of hot chips (200 to 850°C) were applied to various materials. The graph shows the amount of chips burned in. Test winner is igumid HT with up to 850°C hot chips

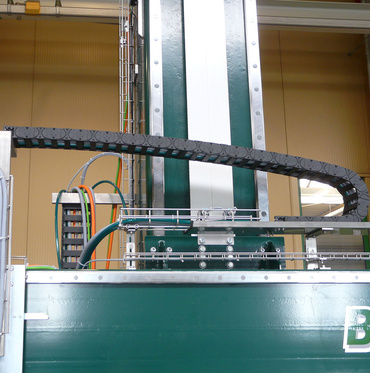

E4 tubes in a gantry milling machine

The energy tube provides reliable protection against hot chips for machines like this milling machine, manufacturing tram switches. Despite the enormous amount of chips and high temperature load, the milling machine runs smoothly thanks to the e-tube.16. Guide more

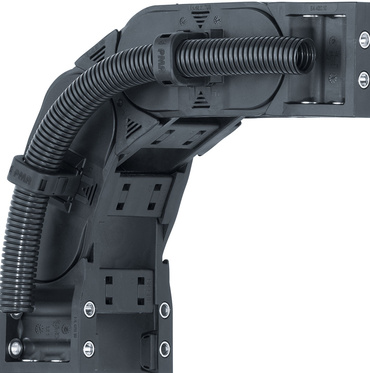

Corrugated guide tubes parallel to the energy chain

TUB extension

TUBs can be fastened to the side of the E4.1L so that corrugated tubes can be guided parallel to the energy chain. They have a feature that makes it easy to fit PMA clips.

Guide corrugated tubes safely

The clip devices on the side of the E4.1L allow corrugated tubes to be clipped in easily so they can be safely guided along the energy chain.

TUBs in use

The TUB extension is used wherever additional cables have to be guided retroactively. The parallel guidance of corrugated tubes is especially popular in mechanical engineering.17. Without camber

Simply rotate the outer link

No camber

By simply turning the outer links, an energy chain with camber can quickly be converted into a no camber (NC) version. NC versions are only required for very special applications, such as hanging application and confined spaces.

Testing of special applications

Products for special applications are tested, such as this storage and retrieval unit. For example, the guidelok slimline F system, which prevents the energy chain from swinging out in storage and retrieval units.

Hanging installation in a palletising machine

Particularly in hanging installation or where space is limited, an energy chain "without camber" is the first choice. Due to its high strength, the E4.1L is ideally suited for such applications.18. Openable extender crossbars

Ideal for routing large hoses

Openable extender crossbars

The E4.1L can be extended by extender crossbars, which increase the interior space of the e-chain. Crossbars can be fitted in various ways: from one or both sides, alternating with standard crossbars and or any combination of these options. Suitable for hoses with an outer diameter of up to 137mm.

Extender crossbars in woodworking

In this wood and sandwich processing machine, the energy chain has been provided with extender crossbars so that the suction hose for wood chips can be guided. The extender crossbars fix the hose securely in the energy supply system and are openable.19. Tight top and bottom contour (e-tube)

All-round protection yet still quick to fill with cables

Hinged lids

The lids of the closed E4.1L e-tubes can be easily opened and completely removed. This allows easy insertion of cables and at the same time the e-tubes close very tightly.System RX

Impermeability tested

In the igus laboratory, the tightness of e-tubes is tested under extreme conditions. This allows the best protection for cables to be developed and the stops remain completely free of chips.

e-tube for protection against chips and dirt

The example shows an e-tube in use in a machine, where it is intended to protect cables from chips and dirt as soon as the machine starts operating. The e-tube is nevertheless easy to open when new cables have to be inserted or old ones replaced.20. Tight mounting bracket

Sealed all round

Can be retrofitted and are highly impermeable. Mounted on the front, the impermeable plastic-and-metal mounting bracket (KMA) keeps dirt and chips away, thus providing ideal protection for the cables.

KMA test in a machine tool

With the tight KMA, the last "gap" in applications in the working environment of machine tools has been closed. The chip-proof plastic-metal mounting brackets with integrated C-rails, protect the cables up to the front edge of the energy chain. At the same time it offers the possibility of strain relief (using CFX strain relief clamps).

KMA in operation on side-mounted energy chain

In this example, the energy chain is flanged on the front side and protected all around with a KMA mounting bracket.21. Strain relief for electric cables

Space-saving and safe chainfix product range

Strain relief

Our strain relief systems have been specifically developed for use in energy chains and dynamic applications. The combination of chainflex cable materials and the plastic components in contact with the chainfix strain relief systems are designed for a long service life of the cables and maximum retention force.

Clamp in tensile strength test

The tensile strength of the chainfix U-clamp is more than three times higher than that of conventional strain relief systems.

Strain relief in a machine tool

Media, data and control lines reliably and safely strain-relieved on this ready-to-install readychain system for machine tools.22. ESD options available from stock

ESD material against static loads

Prevention of static loads due to igumid ESD

Due to the additives used in igumid ESD material, this guarantees long-lasting, durable and maintenance-free motion. To ensure this, each component of the energy chain must have continuous conductivity.