Permanently protected: 3D energy chain for 6-axis robots in automotive industry

Corrugated tubes previously used at the factory ruptured and led to expensive production downtime

In a retrofit process, all axes of a 6-axis robot have now been equipped with multi-dimensionally moving energy chains. The complete robot accessories package includes 3D chains that guide and protect cables and hoses during all movements, fibre-rods for directional preload, as well as adapters, protectors and a chain for rotary movements. Since then, there has been no more downtime.Profile

- What was needed: twisterchain, triflex R, triflex RS

- Requirements: the protective hoses provided by the factory are permanently torn or had worn through, this led to stoppages; the company was therefore looking for a solution that would provide safe and durable protection while being able to accommodate the complex movements in all axes

- Industry: automotive industry

- Success for the customer: on the various axes, the different chain applications demonstrate their strengths perfectly; they guide the cables safely in complex motion sequences, reduce downtime and bring stability and safety

Problem

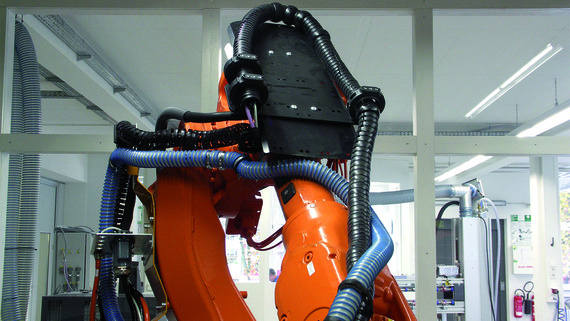

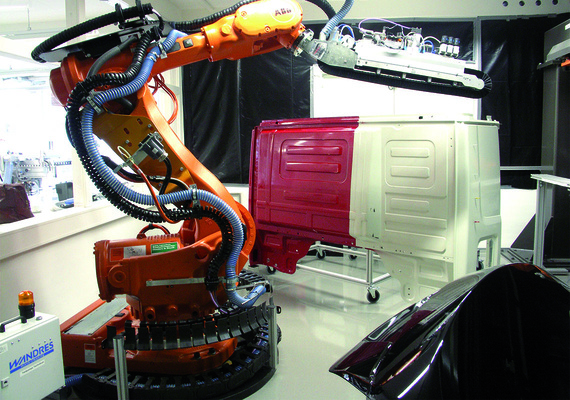

Wandres GmbH specialises in the development and production of brushing and air cleaning systems. The removal of dust, fibres and minute particles from surfaces is a prerequisite for many manufacturing processes in order to produce high-quality products, especially in the automotive industry. In this environment, 3D micro-cleaning before final painting, a special cleaning process from Wandres with the so-called robotic sword brush, proves its worth.In the Wandres technical centre, a multi-axis robot is used to run endurance tests to check the cleaning quality and results of the special brush on a wide variety of surface structures. The robotic sword brush is particularly suitable for cleaning complex geometries that cannot be reached with alternative methods. The travel speed of the robot is approx. 300 to 400mm/s. Both cycle and continuous operation is possible.

The basis of the cleaning process is the company's patented "Ingromat" process. This is a special micro-moistening system. It significantly minimises frequently occurring electrostatic charges and safely removes adhering dust and particles.

After the 6-axis robot had been in operation for about two and a half years, a new solution was sought for the cable guidance. Originally, all robot cables had been protected against mechanical damage with the protective hoses provided at the factory. However, it permanently cracked or wore through, with the result that the entire test system came to a standstill. The company was therefore primarily looking for a solution that would not only be secure but also provide lasting protection.

Solution

For more than 20 years, the specialist for surface cleaning has been working with our products for cable guidance. It is used in almost all Wandres cleaning systems. Here, too, all six axes of the cleaning robot were equipped with 3-dimensionally moving energy chains.For the circular movement of the rotary axis, a twisterchain proves its worth. The spiral-shaped modular energy supply system is suitable for circular movements of up to 540° and is completely pre-assembled on request. Hoses and cables are safely guided, abrasion is significantly reduced, smooth operation increases. On axes 2 to 6, the multi-dimensionally moving energy supply systems from the triflex R family reduce downtime and bring stability and safety, from large welding robots to small palletising robots. Due to the round design, the chain glides over the outer contour of the robot, does not get tilted or hooked.

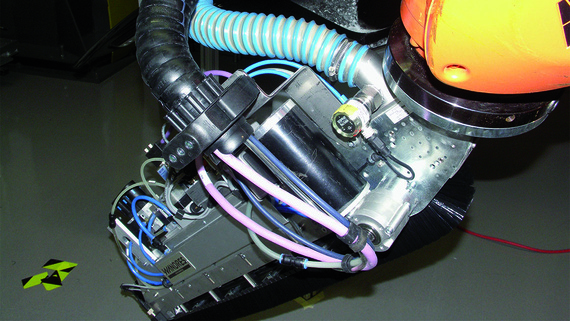

Axes 2 and 3 of the robot are equipped with the triflex R light variant, a functionally reliable solution for less complex movements. For axes 4 to 6, however, the compact triflex RS set is used. With the universal module, the chain is guided parallel to the robot arm to save space. Applications can be implemented in the tightest of installation spaces. Fibre-rods within the chain create a pre-tension to achieve complete or partial stiffening. Automatic retraction mechanisms avoid looping and cable stress at the robot head.

The "trailer principle" enables the high tensile strength of the system. The individual elements are connected like a trailer coupling (ball and socket principle). This allows a high degree of movement in all directions. In addition, there is a defined freedom of movement in all directions, which also increases the service life of the chain, cables and hoses.