Cables and energy supply systems prove themselves in high-speed injection moulding machine

Hekuma has been using chainflex control cables and E6 energy chains for more than 10 years

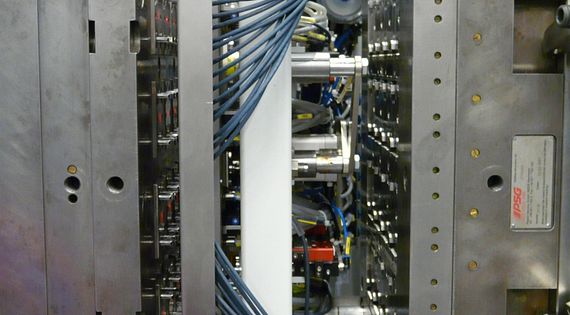

Hekuma's high-performance automation systems for the plastics industry operate with cycle times every second. For the energy supply system of the grippers, this means that the first million strokes are achieved after only four to six weeks - and that under adverse environmental conditions such as heat, high acceleration and movement in two axes. This is where our chainflex cables prove their worth and are subjected to almost as much stress as in our in-house test laboratory.Profile

- What was needed: chainflex CF9 control cables, energy chain series E6

- Requirements: The extraction robot reaches extreme speeds, whereby the extraction time of the injection moulded parts is less than one second. Within a few months, several million double strokes are already achieved, and this at very high accelerations of up to 10g.

- Industry: Plastics machinery, injection moulding machinery

- Success for the customer: Thanks to cores wound in bundles, CF9 control cables with a tight bend radius remained strong for years even under extreme bending stresses and high dynamics. The jacket made of abrasion-resistant TPE ensures very good abrasion properties. The E6 energy chains also handle the high dynamics reliably and without failure.

Problem

Fast - faster - Hekuma: The company Hekuma stands for high and maximum performance automation of complete systems for plastics processing, which are used for example in medical technology, the automotive industry or in the production of consumer goods. In its injection moulding machines, the manufacturer automates not only removal, but also upstream and downstream processes such as the punching of contacts or the insertion of stamped parts into the injection mould. In doing so, they work at extreme speeds. Typical cycle times are four to six seconds, with some achieving removal times of less than one second. This is also the case, for example, with a system from Hekuma with a 64-cavity mould for the production of laboratory sample containers, which is clocked with a cycle time of 5.5 seconds.However, due to the high pace of production, an outage of just a few minutes would quickly lead to tens of thousands of missing parts. As a result, it is often the mechanics that set its limits, but often also the electronics. Hekuma is thus moving at the (speed) limits of mechanical engineering - and the question arises as to which cables and which energy chains the grippers are equipped with. With the typical cycle times, several million double strokes already accumulate within a few months, and this at very high accelerations of up to 10g. A conventional cable would fail under these loads after just a few days.

Solution

The cable solution chosen by Hekuma lasts for years. And has therefore also been an integral part of the injection moulding machines for over ten years. Specifically, the company relies on the control cables of the CF9 series with cross sections of 0.25 to 0.34mm2 as INI cables. The cables from our chainflex product range have been specially developed for use in energy chains. Only optimised stranded wires are used in the individual cores, which are not too thin and not too thick in their wire thickness. The individual cores are stranded in such a way that no "corkscrews" can occur. This is where cores wound in bundles help, in which the cores are first stranded with a short pitch length and the resulting bundles are in turn stranded to form an overall structure. This structure takes place around a high tensile strength centre element. This means that the stranding remains strong even under the highest bending stresses and high dynamics. The jacket made of special abrasion-resistant TPE ensures very good abrasion properties and the small bend radius of 5xd is also perfectly adequate. The small bend radius is critical because space for tool and workpiece handling is often extremely limited.While the moving cables are partly exposed, they run in chain guides on the main axes. Here, Hekuma has selected the plastic energy chains of the E6 series as the standard system. The requirements here are similarly high as for the cables: due to the very short strokes, constant vibrations occur in the cable system, which act like short blows. This causes a very high stress on the chain and cable, quite different from constant rolling movements.

The heavy injection mould is completely open for only 0.8 seconds. In this short time, the gripper must move into the mould, remove the finished plastic parts with a movement in the second axis, before the mould closes for the next shot.

Holger Weber, electrical designer at Hekuma GmbH

Comprehensive chainflex product range - also for condition monitoring

Hekuma is at the forefront of exploring new possibilities in drive and control technology. This applies to the introduction of new technologies in processing and assembly, but also to the fundamentals of automation technology. The goal is to integrate even more electronics and sensor technology in the future - for example, for the status analysis of machine components. In any case, there is no need to worry about the energy supply: even with even higher dynamics, the chainflex CF9 cables and the E6 energy chains provide a system for absolute high-speed automation.Within the standard CF9 cable, chainflex offers a wide range of further possibilities. Reliable cables for applications with larger radius and fewer cycles are available as well as cables for the smallest radii. The CF9 used here is to be classified in the high-end range of the product line. Users who want even more resilient cables can use solutions with special alloys that can withstand loads even at a radius of 4xd. But for Hekuma - and also for other demanding customers - the CF9's property profile is completely adequate.

Here you can find the products used

CF9 control cables

- Four-year guarantee

- Use the price check to always find the cable that costs least and is guaranteed to work

Learn more

E6 series energy chain

- High strength and service life

- For high fill-weight loads on long travels

Find out more here