Pre-assembled energy supply systems for measurement and control systems

Profile

- What was needed: Reliable pre-assembled energy chain system

- Requirements: Use of 360 days/year, heat resistant, resistant to oily and dirty air

- Product: readychain® harnessed energy chain

- Application area: Measurement and control technology

- Success for the customer: Pre-assembled energy supply systems from igus ensure high quality in measurement and control technology, with high cost advantages at the same time

About measurement and control systems for films:Blow film extrusion is a very sensitive process. Many mistakes can happen that have a direct effect on the product, the film. To achieve uniform widths and thicknesses, sensitive measurement and control technology is used. For over 30 years, Kündig Control Systems has been developing ever new solutions for measuring films. The devices display the measured data immediately and form the basis for ensuring the error-free production of blow films. The spectrum for films is enormous. The measurement and control technology of Kündig Control Systems is a pure niche product. There are only a few suppliers worldwide who have specialised in this topic.

The challenge

The requirements in the industry have changed over the years. Today, Kündig Control Systems makes much more compact systems. The pre-assembled energy supply system mounted on its side should be embedded in the aluminium slewing ring and rotate very slowly around the film. At 180° the energy chain would reach the turning point.The ultimate goal is accurate measurement. For this reason the system moves extremely slowly. It is adapted to the process, which needs rest, otherwise disturbances or faulty production can occur. The demands on the measuring system and energy supply system are therefore very high in blow film extrusion. The entire process cannot simply be stopped or shut down. As a rule, the devices are in use around the clock, 360 days a year. In addition there is heat, oily and dirty air. The energy supply system is only used for thickness measurement. With this capacitive system, measurements are made in the µ range.

Solution

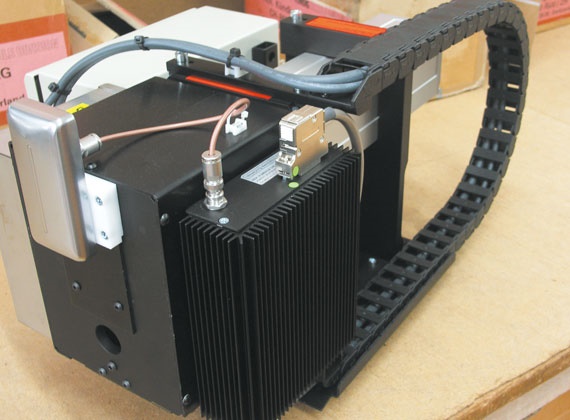

For the Kündig measurement and control systems, two readychain systems or pre-assembled energy supply systems were designed, each according to the longest travel. There is plenty of space in the slewing ring. By limiting the number of systems to two, a reduction in costs could be achieved as well as lower handling and logistics costs.The cost savings go even further. In order to be able to drive the defined reverse sag, the radius limiting cam of each used individual chain link had to be milled off earlier. Although the result was a harmonious movement, the elaborate post-processing could not be maintained for reasons of economy. Today, every tenth chain link is turned by 180° and a small part is milled off before it is docked to the standard chain again. Although the reverse run is no longer harmoniously round, the entire solution works. The savings are in the three-figure range due to the pre-assembly per system.

Energy chains of the system E2/mini are used. The chain can simply be opened and the chainflex cables inserted and not drawn in. This allows them to be replaced quickly in the event of damage.

To the readychain® overview

motion - magazine for energy chain systems®

Improve the performance of your machine ... Cost down.

In this igus® magazine you will find numerous possibilities and application examples of how you can bring your tech up and/or cost down with ready-to-install energy chain systems.Order your personal copy here