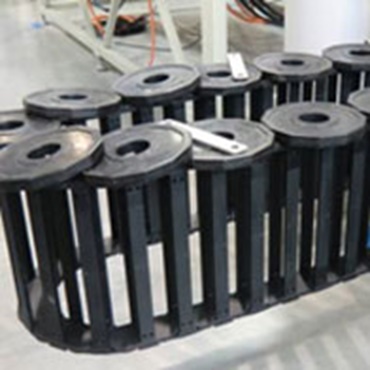

igus® e-chain system® with E4/4RHD rollers – for heavy-duty uses

The reasons why the igus® roller chain from the heavy-duty series is particularly suited for rough environments

High stability, low wear, and a maintenance-free roller system to reduce push/pull forcesRoller energy chains

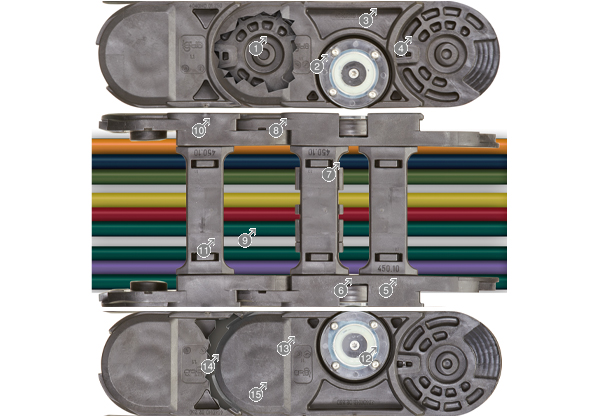

1... Large pin/bore connection

High push/pull forces and reduced wear due to tight tolerances.

... travels greater than 800 m possible... low wear

... low elongation of the entire system

"In comparison to the standard E4/4, the pin strength is increased by up to 40%. “

Details of working principle

Large pin/bore connection

Large pin/hole connections with tight tolerance provide a high push and/or pull force absorption potential. Due to the tight tolerances and the resulting, almost complete zero backlash, very high accelerations can be achieved and there is very little wear.igus® tested

Tensile test with Zwick material test equipment

We test every energy supply system with a "tweak testing machine" at the igus® laboratory for compressive/breaking strength to provide reliable specifications on max. additional load and unsupported lengthTest 3992:More than 30.000 N tensile strength

Application example

The world's longest travel with igus® e-chains® and chainflex® cables travel of 615 m

The longest plastic distance in the world covered by an igus® e-chain® was designed and delivered for the largest power supplier in the Czech Republic, the CEZ Group. The distance covered is 615 m.The stable pin/hole connection enables such long travels thanks to high push/pull force absorption.

The longest travel with plastic energy chain

2... low forces

The integrated, maintenance-free rollers significantly reduce the incurred forces.

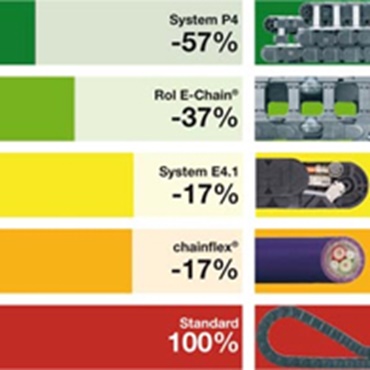

... maintenance-free rollers reduce push/pull forces by up to 75%... increased additional loads on long travels

... reduction of the required drive power

Details of working principle

System RX

igus® tested

Application example

3... Heavy Duty

… no restrictions with respect to dirt loads… high additional loads

… heat, moisture, and cold … no problem.

Details of working principle

igus® chainflex®

igus® tested

Test 1442

Long-term technology in the igus® labApplication example

4... Rugged, rectangular stop dog

… high stability and rigidityDetails of working principle

Double, rectangular end stop dog

More than two stop dogs cannot be, or can barely be synchronized. Due to a rectangular shape, the force distribution is much better than in a round stop dog (surface pressure formula, p = F/A).igus® chainflex®

igus® tested

Fracture test at the igus® laboratory

We test every energy supply system with a "tweak testing machine" at the igus® laboratory for compressive/breaking strength to provide reliable specifications on max. additional load and unsupported length.Application example

5... low wear

For a long service life on long travels due to wide glide surfaces and wear allowances

up to 9 mm wider glide surfaces in comparison to the standard System E4/4Details of working principle

Wider glide surfaces

Wider glide surfaces + wear allowanceigus® tested

Application example

Longest travels with e-chains®

Reliably solve long travels with igus® e-chains®, like the E4 series here in a gantry crane, guided in an igus® guide trough for 220 m.6... fast

Even on long travels, igus® E4/4 RHD chains can achieve speeds of up to 6m/s.

... speeds on long travels, even in heavy-duty applications.Details of working principle

igus® tested

Application example

7... Cable-friendly interior separation

For higher service life due to rounded base

... nearly halve the cable wear... less parts, more possibilities

Details of working principle

Cable friendly polymer crossbars

Smooth, cable-friendly and rounded contour provides for a long service life of the cables and hoses. In addition, a better and more cable-friendly interior separation can now be implemented with less standardized components.igus® tested

Wear tests

With the new rounded separators, the wear of the cables could be almost halved.Test 3748:Separator 301 compared to new version 45.1 The matching pair of plastic and jacket material also turns out to be the best here.

Application example

8... Modular

The modularity of igus® systems facilitates convenient extending, shortening, expanding, and replacing.

… "infinite" width extension with extension links… shorten and extend directly on location.

Details of working principle

igus® tested

Application example

9... Everything in one system

Cables, hoses, fibre-optic cables .. everything in a single system

... reliable data and power transfers in an e-chain®... dynamic hydraulics guided reliably.

… the world's only energy supply system that can reliably guide all media at the same time.

Details of working principle

igus® tested

Application example

10... Reinforced side plates

Highly durable in outdoor environments due to side plate reinforcements of up to 9 mm.

... extended running performance guaranteed at low maintenance... for long travels in outdoor environments.

"Up to 9 mm reinforced side plates when compared to the standard E4/4"

Details of working principle

reinforced side plates

Reinforced side plates nevertheless allow loads from push/pull forcesigus® tested

Application example

11... To be opened from both sides

Convenient and fast filling with crossbar system that snaps open on both sides (along the inner and outer radius)

... convenient replacement of cables... good accessibility in all positions

Details of working principle

Simple to open

Crossbars can be opened with the igus® screwdriver. The e-chain® is then conveniently filled from both sides.igus® tested

Fracture test at the igus® laboratory

Countless installation kits in our lab prove the easy and convenient filling of e-chains®.Application example

12... Maintenance-free

Maintenance-free rollers with encapsulated stainless steel ball bearings

... maintenance-free, pre-lubricated and encapsulated stainless steel ball bearings for any environment... various roller types for various applications.

Details of working principle

igus® tested

Application example

13...Long travel

By using roller chains, travels of up to 800 m can be achieved.

... reduced push/pull forces… rolling instead of gliding.

Details of working principle

igus® tested

Application example

14... Torsion stable due to tongue and groove

For high stability at lateral accelerations and high torsion resistance due to "interlocking feature"

... high additional loads for unsupported and gliding operation.... ideal for high torsion forces

Details of working principle

Tongue and groove design

The chain links are "hooked into one another", which provides for extremely high torsional stability of the e-chain® and for high unsupported lengths even in side-mounted applications.igus® tested

Break test with Zwick material test equipment

Here we also test every system for maximum load capacity to get reliable information on service life, which is also incorporated into our online service life predictor.Test 40092 m E4 e-chain® with 7.7 kg additional load

Application example

Hanging application

A E4/4HD chain on a container crane. The tongue and groove and the reinforced configuration ensure reliable operation even in stormy conditions.15... Conductive

Compliant thanks to the igumid ESD material

... igumid ESD corresponds to classification Ex II 2GF... conductive in unsupported and gliding operation

Details of working principle

igus® tested

Application example

Sample order