Do not enter

Special bus cable for chip card readers in a lift system

A group of lifts installed in a savings bank building serves eleven floors and the basement area. Customers are not permitted to access all levels. This is enforced by an access control system. The bus signals required for this purpose are transmitted via a special cable with a structure proven to withstand the high push-pull forces associated with the freely suspended application.

"In 2011, we replaced an existing purely mechanical lift system at our site in Ludwigshafen," reports Michael Krauß, Head of Building Organisation at Sparkasse Vorderpfalz. "There are two passenger lifts with a nominal load of 650kg each and one goods lift with a nominal load of 1.1t. The special feature is that the group of three travels in a common shaft. The lifts open up the whole house. The system is controlled in such a way that part of the floor is only accessible to employees. And if necessary, further floors can be blocked at any time for any period of time. The relevant data is stored online by the lift manufacturer. One phone call is enough.”

The requirement profile of the Sparkasse was clear in advance. The existing access control system for the employees, which consists of card readers, was to be transferred to the lifts so that access to the bank and operation of the lifts works via the existing chip card. However, the technical implementation turned out to be not so easy: the elevator manufacturer could not offer a bus cable that would have made it possible to connect the existing card readers. The solution came from the electrical installation company Keipp from Ludwigshafen, which carries out a wide range of electrical and installation work for the Sparkasse.

The requirement profile of the Sparkasse was clear in advance. The existing access control system for the employees, which consists of card readers, was to be transferred to the lifts so that access to the bank and operation of the lifts works via the existing chip card. However, the technical implementation turned out to be not so easy: the elevator manufacturer could not offer a bus cable that would have made it possible to connect the existing card readers. The solution came from the electrical installation company Keipp from Ludwigshafen, which carries out a wide range of electrical and installation work for the Sparkasse.

"Our contact person recommended that we use an extremely robust bus cable for long, hanging travel paths from the world of industry," recalls Krauss. "However, back then it was still in the testing phase. We decided to go ahead and use it anyway. We've never regretted that decision. “

Technical advantages of the special cable

The lift system features a special chainflex® cable, CFSPECIAL182.045, for hanging applications from igus® GmbH, based in Cologne Germany, which exceeds the requirements of all applicable standards and directives, and in tensile strength it significantly exceeds these requirements. The CFSPECIAL series introduced in 2012 expands the standard product range by adding cables for highly demanding tasks. This series also includes special cables, such as for the rail industry, and cables with high tensile strength.

The special cables offer a wide array of benefits. They provide solutions for applications that go beyond normal energy chain applications. The growing product range of special cables is geared towards the requirements of customers from all industries, for which specific solutions are developed and tested.

The lift system features a special chainflex® cable, CFSPECIAL182.045, for hanging applications from igus® GmbH, based in Cologne Germany, which exceeds the requirements of all applicable standards and directives, and in tensile strength it significantly exceeds these requirements. The CFSPECIAL series introduced in 2012 expands the standard product range by adding cables for highly demanding tasks. This series also includes special cables, such as for the rail industry, and cables with high tensile strength.

The special cables offer a wide array of benefits. They provide solutions for applications that go beyond normal energy chain applications. The growing product range of special cables is geared towards the requirements of customers from all industries, for which specific solutions are developed and tested.

"We fabricate appropriate cables for virtually any application area, and in this process we rely on a wide variety of materials and processes," explains igus® Product Manager Andreas Muckes. "Depending on the design, this is possible even for lengths of 500 metres." In our in-house lab, the different cables are tested, primarily for their dynamics over long and short paths. Radii and torsion are important aspects here. The task is always to find the right cable concept for demanding motions. As a result, over 2 billion test cycles are run each year as part of research and development.

"Bulletproof" special cable

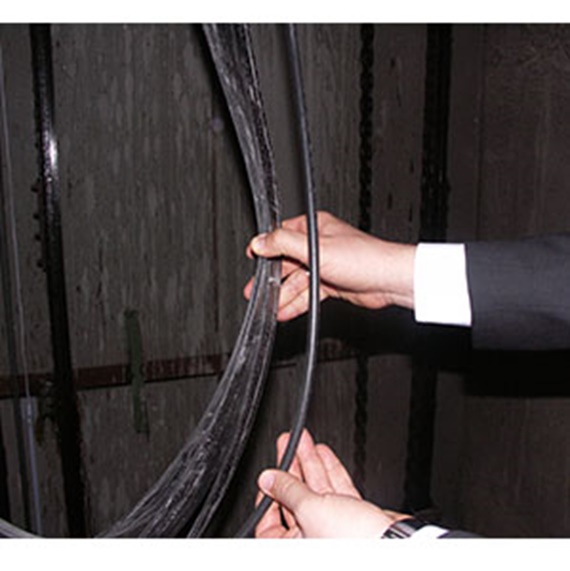

The special cable for data transmission in the lift system hangs freely in the shaft and easily absorbs the weight forces that occur. It has the same four-pair core structure as a normal Ethernet cable and has a TPE inner jacket and an extremely rigid shield braiding. The difference to standard bus cables lies in their jacket structure. The black outer jacket is made of a low-adhesion, highly abrasion-resistant PUR compound with an embedded aramid Kevlar fibre. "The material is similar to that of a bulletproof vest," says Muckes. The technical structure sounds simple, but it is extremely sophisticated: the special fibre is braided over a thin jacket. This sinks into the material during the subsequent production of the outer jacket and permanently absorbs all external forces.

In the test laboratory it could be proven that the special cable is around 15,000 percent above the standard required in the corresponding DIN VDE 0298 in the tensile test. Pulled with 2,919N, the cable is not torn off and the data transmission remains permanent. The cable length in the system is 74 metres.

The special cable for data transmission in the lift system hangs freely in the shaft and easily absorbs the weight forces that occur. It has the same four-pair core structure as a normal Ethernet cable and has a TPE inner jacket and an extremely rigid shield braiding. The difference to standard bus cables lies in their jacket structure. The black outer jacket is made of a low-adhesion, highly abrasion-resistant PUR compound with an embedded aramid Kevlar fibre. "The material is similar to that of a bulletproof vest," says Muckes. The technical structure sounds simple, but it is extremely sophisticated: the special fibre is braided over a thin jacket. This sinks into the material during the subsequent production of the outer jacket and permanently absorbs all external forces.

In the test laboratory it could be proven that the special cable is around 15,000 percent above the standard required in the corresponding DIN VDE 0298 in the tensile test. Pulled with 2,919N, the cable is not torn off and the data transmission remains permanent. The cable length in the system is 74 metres.

Normal bus cables cannot be used due to their inherent weight. Their lack of a carrying member means that they can only bear loads up to 15 N/mm². Taken together, all these facts mean that the freely suspended cable could be over 1 kilometre long before having to contend with any decrease in performance. "For us, this means that we could theoretically increase the height of the building significantly," states the construction organisation manager. Initially, an additional cable was installed in the lift system to provide an added safety margin to be on the safe side and to make it possible to measure the data records that were generated. The lift systems are used very frequently. Just under six months after the system was commissioned, it had already made some 56,970 trips. After two years, they will have easily surpassed a figure of 160,000 without any hint of a malfunction. "The system is certainly not going to reach the maximum number of trips for which it is certified. A new lift control system will be installed first well before that," says igus sales advisor Eugen Kowalczyk with confidence. On the other hand, chainflex® cables for industrial applications are designed for very small bend radii, high numbers of cycles, high speeds, high accelerations and demanding environmental conditions.

Error-free data transmission

This particularly durable special cable with aramid fibre was originally developed for storage and retrieval machines used in high-rack facilities with racks up to 100 metres high. At this height, data transmission problems may occur with standard cables. The chainflex cables also demonstrate their performance capacity in movable camera systems in forklift applications where a camera is integrated into the fork arm and the cable is wound around drums. All these applications have in common that data transmission must occur error-free and safety is of great importance. Moreover, the processes must never come to a stop. "The lift just has to work. In order to ensure smooth customer traffic, it cannot stop unexpectedly," says the Director of Facility Management at Sparkasse.

This particularly durable special cable with aramid fibre was originally developed for storage and retrieval machines used in high-rack facilities with racks up to 100 metres high. At this height, data transmission problems may occur with standard cables. The chainflex cables also demonstrate their performance capacity in movable camera systems in forklift applications where a camera is integrated into the fork arm and the cable is wound around drums. All these applications have in common that data transmission must occur error-free and safety is of great importance. Moreover, the processes must never come to a stop. "The lift just has to work. In order to ensure smooth customer traffic, it cannot stop unexpectedly," says the Director of Facility Management at Sparkasse.

Even though this cable is a special solution, developed for the highest demands, However all of the experience flows into the variety of standard chainflex® products. This way, the customer is always on the safe side and receives the right cable for any requirement.