Energy supply – protected and flexible

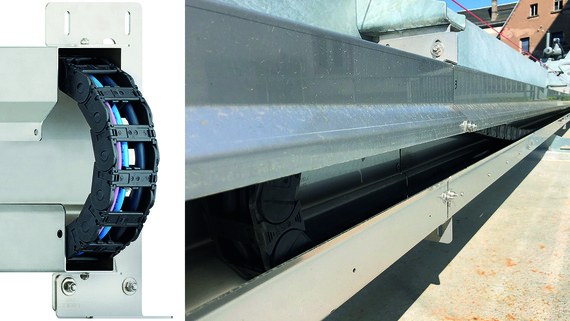

A basic flizz e-chain on a water turbine rake cleaner saves space and maintenance costs.

The Schlossmühle hydroelectric power station in Rochlitz, Saxony now has a new rake cleaning system. The H-cleaner made by Muhr, a global specialist for such systems, uses a proven standard for energy supply to traversing carriages: igus's basic flizz system.Profile

- What was needed: basic flizz energy supply system, chainflex cables

- Requirements: A safe, compact cable routing system to replace the current festoon system. The new solution must also be easy to install and maintain.

- Sector: Renewable energies, hydroelectric power plants

- Success for the customer: The basic flizz was installed in only an hour and a half. Today, just 30 centimetres of installation space are required for the 15-metre cables. The energy supply system is well hidden and yet easily accessible for maintaining the cables or adding new ones.

Problem

The Schlossmühle in Rochlitz, Saxony has been producing electricity since 1994. To protect fish, the operator has now invested in the reconstruction of the turbine house inlet and had a new rake installed during the process. The rake is a cleaning system that removes the floating debris that collects in front of the rake and ensures that water is supplied to the turbine. After various offers, the decision was made for an Erhard Muhr GmbH rake system.Muhr offers hydroelectric power station operators a comprehensive range of rake cleaner designs (vertical, horizontal, with various booms, etc.). Its systems are in use all over the world, and each of them has been individually adapted to the case for which it is being used. For the Rochlitz project, Muhr suggested a horizontal H-series rack system. The cleaning arm moves horizontally past the rake, pushing the debris into the discharge channel. The cleaning arm is mounted on a traversing carriage moved by a rack-and-pinion drive. The driving force is provided by a direct drive from a three-kilowatt low-speed motor that, like the rest of the components, is suitable for underwater operation.

While project negotiations were ongoing in Rochlitz, Muhr engineers were developing a new solution for supplying energy to the H-series cleaning arm. The reason for this was the high installation effort and the previously used festoon system with flat cables. Two power cables and three sensor cables were routed to the motor mounted on the cleaning arm. Since all standard connection components such as seals and bushings for round cables were designed, the connection of the flat cables required a great deal of effort. In addition, the free-hanging cables could become entangled, and the cable station set-up needed about two metres of space. This prompted planners to look for an alternative.

Solution

Muhr found this alternative in our basic flizz system. It is a complete solution for energy supply to moving components in such systems as sewage treatment plants and energy and crane technology. The system consists of an energy chain from our E4.1 modular system, which is filled with chainflex cables and guides them safely in a weatherproof stainless steel enclosure. The advantages were obvious as soon as the first basic flizz was mounted on the rake cleaner in Rochlitz. While it normally took the fitters on site a day to install the energy supply system, they were able to complete the task in an hour and a half. And the cable trolley for the moving energy supply, which is about 15 metres long, required only 30 centimetres of installation space. This not only means more room but also saves cable length and copper.Other advantages the Muhr engineers saw were the energy chain guidance system, which is protected on three and a half sides, and the freely suspended cable routing, which prevents cables from freezing in ice and snow. The basic flizz is mounted more or less invisibly behind the linear drive but is easily accessible if required. New cables can be added without any problems and there is no need to replace the entire cable package, as there is with a festoon system. This is why Muhr now only uses the basic flizz system for its H-series.

Two sensors measure water levels upstream and downstream of the rack and give the signal for the system's PLC to start the cleaning process. At a specified difference the PLC initiates the cleaning process that takes only seven minutes. The situation at the Rochlitz Schlossmühle rake is monitored by two cameras. This modern technology and the durable energy supply system will contribute to efficient hydroelectric power plant operation for many years.