Technical data:

- What was needed: A dosing machine in which autocaps ensure that the dosing head closes effectively and automatically after each dosing operation

- Requirements: Low costs, very low dry friction on metallic materials, no stick-slip effect, long service life, resistance to dirt, quiet operation

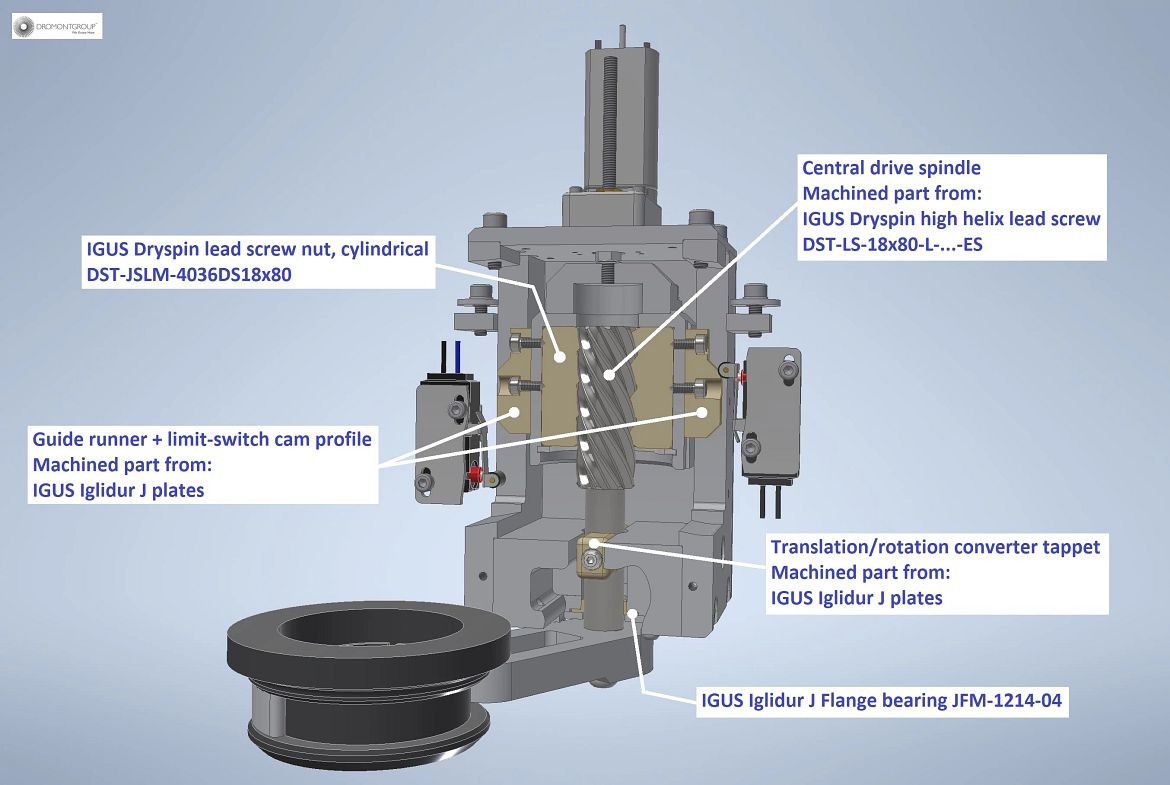

- Products used: dryspin® high helix lead screws with matching DS18x80 lead screw nut, iglidur® J flanged bushings, individual iglidur® J bar stock plates

- Success for the customer: The dosing head closes after each dosing procedure so that the fluid remaining in the nozzles is prevented from drying out. The igus® solutions also allow translation and rotation with a single actuator instead of using two separate actuators or a helical actuator.

Need more information? Contact us here

Problem

The system, called "Autocap RT," is used in Dromont dosing machines to automatically close the dosing head after each dosing process. This protects the nozzles by keeping the liquid remaining in them from drying out when dosing is finished. The next dosing command causes the system to open the head again automatically. The movement of a special cap equipped with a humidification system effects closure. The cap is mounted under the nozzle area of the dosing head to create a closed, moist environment. The contents are kept liquid while a seal is pressed around the edge of the head, preventing dispersion of the moist atmosphere.

These Dromont machines are used in a variety of areas:

- in publicly accessible shops and shopping centres (paint shops, Brico, various DIY stores, etc.)

- in industrial environments as stand-alone dosing devices

- in industrial environments as components of dosing systems

Moreover, the following challenges were overcome:

- vertical displacement and horizontal movement with a single drive

- An optimally effective, uniform seal when the head is closed

- quick activation (in less than a second)

- very low actuation forces

- simple adjustment during installation

- absolutely no maintenance work

- reliability over the machine's entire service life (more than ten years)

- low overall size

- quiet operation

- low costs

Solution

The lead screw drive is at the core of the system. The high reversibility, made possible by the high efficiency and pitch angle of the dryspin thread, allowed the use of a single actuator for the two locking movements. So the cap can be vertically detached from the head and removed horizontally from the dosing area. The lead screw and nut are actuated with vertical translation to achieve joint vertical movement or rotation of the lead screw around its own axis, depending on the execution phase. The two phases of translation and rotation were separated with a driver made of iglidur J, which is firmly connected to the dryspin lead screw. It has an L-shaped guide whose vertical and horizontal sections allow only vertical translation or rotation of the dryspin lead screw. This allowed two completely different movements (in terms of both type and torque) to be achieved with a single, very simple linear drive.igus components were essential for the following:

- actuation in two separate phases (translation and rotation) with a single actuator instead of two separate actuators or a screw-shaped actuator, which would have caused various additional problems (cost, handling impairment, lubrication, etc.).

- keeping the required actuation forces very low (less than 800g), which allows use of a very small, low-power actuator. This is critical, since the system must be housed in the small space available inside the machine dome.

- the entire movement of the head bolt carrier (cap) must be carried out with a very short actuation stroke: the total linear actuator stroke is 18mm, 8mm for the vertical movement and 10mm for rotating the cap carrier 45°

- keeping the overall dimensions of the entire system extremely compact

- extremely fast actuation (approx. 0.5 seconds for the entire opening/closing stroke) thanks to extremely compact system kinematics

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here