Technical data:

- What was needed: A CNC machine that enables true freestyle milling

- Requirements: Functionality without lubrication or maintenance, versatility, low price

- Products used: High helix lead screw with special geometry, plastic nut made of the high-performance polymer iglidur J4

- Success for the customer: Typical of all machines is the high functionality and versatility at an affordable price - after all, many customers are private buyers. The M series can process plastic, wood, aluminium, and brass. The machines can also be used with accessories for laser cutting, plotting, engraving, hot cutting, and even 3D printing. It all fits with the "Think it – make it" slogan.

Make a contact request

Linear drives for "freestyle" milling

Stepcraft CNC milling machines give hobbyists and industrial users new freedoms, turning their CAD drawings into reality. The M series is particularly versatile. The tool moves with maintenance-free dryspin lead screws from the igus modular design system.Most users of the Stepcraft M serieshave one thing in common: they are creative. What they produce with the machine cannot be generalised because of its versatility. Peter Urban, CEO of Stepcraft GmbH & Co. KG, says, "The majority of our customers are hobbyists in the model-making industry and we have reached a large proportion of this target group. However, the M series is also used in toolmaking and small series and prototype production, for example."

"Think it – make it"

In 2012, Stepcraft developed its first CNC milling machine for model-making and subsequently built up an entire product range. What is typical of all its machines is high functionality and versatility at an affordable price, – which is important, considering that many customers are private buyers. The M series can process plastic, wood, aluminium, and brass. The machines can also be used with accessories for laser cutting, plotting, engraving, hot cutting, and even 3D printing. It all fits with the "Think it – make it" slogan."Freestyle Milling" in three dimensions

This applies to the M series even more than to the other Stepcraft CNC machines. Says Peter Urban, "The M-Series is the world's only CNC machine that allows true freestyle milling." This means the user can remove the machine table and machine large workpieces underneath the machine.And the freedom goes even further: with optional vacuum rails, the machine can also use suction onto the wall or ceiling and machine. It is fitting that most buyers accept the offer to purchase their machine in kit form and assemble it themselves.

Says Urban, "This is not only because of cost. Our customers simply enjoy building and want to understand the machine they are working with."

Cost-effective designing – without compromising quality

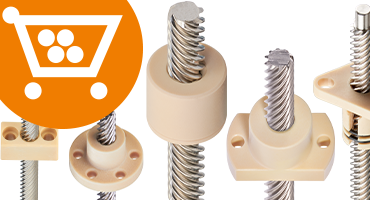

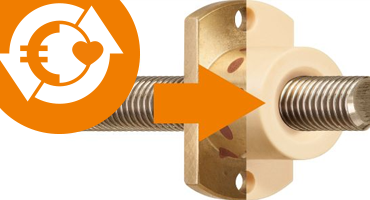

Since hobbyists are cost-sensitive, Stepcraft's designers are concerned not only with the best functions and the greatest flexibility, but also with the cost of each innovation. Urban continues, "Among the options we offer for the M series is an oscillating tangential knife. As a purchased part, it would have cost us €1,100. We've developed one that's at least as versatile and robust, but only costs €350." When it came to the question of how to move the milling head (or any other tool) in three axes, the designers had to not only find the best technical solution, but also keep an eye on the costs. Says Urban, "We have our own test rig for drives. There we tested different linear systems such as round lead screws and trapezoidal lead screws with gunmetal nuts in direct comparison." The tested parameters included noise development, precision, and wear – and the igus dryspin lead screws scored best.dryspin high helix thread with special nuts

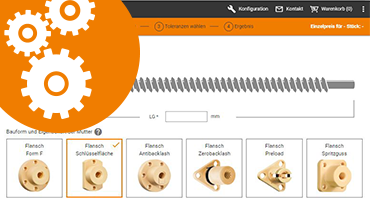

The test was on a lead screw with high helix thread with special geometry in which a plastic nut made of the iglidur J4 high-performance polymer with incorporated lubricant moves. The two components form a highly efficient, maintenance-free, durable linear drive that can be positioned precisely and adapted well to individual requirements. These lead screws are used in all three of the M series axes.Stepcraft procures different lengths for the x and y axes because the machines are available in several table sizes. The lead screws are moved by NEMA 23 motors. Injection moulded double nuts with a customer-specific outer contour travel on them, and Stepcraft connects them with an aluminium bracket. This provides the desired preload and avoids backlash.

Lead screw drives are subjected to heavy loads

The dryspin linear axes are subjected to high loads in this application, as Peter Urban explains: "When the tool mills a circle into the material, for instance, high and overlapping forces act on the axes." Because the machine processes a wide variety of materials at very different feed speeds, the possibility of vibrations cannot be completely ruled out from a design point of view. In this case, Stepcraft designers have found that a drop of oil helps as a damper: "This produces even better running behaviour." A detail improvement that igus has made in the current dryspin series also has a positive effect: The plastic nut threads are no longer cut subsequently, but cast directly via a driven tool with a turning core. Mechanical machining can therefore be dispensed with, meaning that the cast skin is retained and the nut runs with even less friction.Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form, and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here