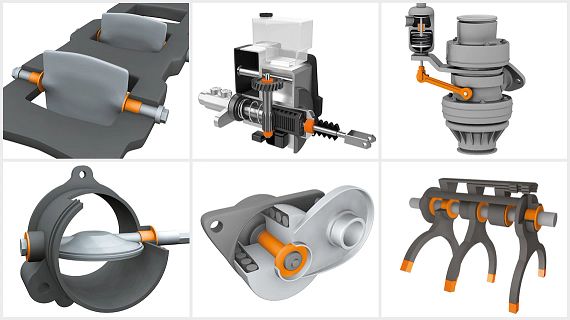

Bearing technology for the engine compartment

Reduce vibration and corrosion on turbochargers, throttle valves, etc.

Whether it's a variable intake manifold, shift fork, belt tensioner, exhaust gas recirculation valve, throttle valve or turbocharger, things get hot in the engine compartment. To reduce friction and wear in the various applications, the selection of the right plain bearing is of great importance. We would be happy to assist you in your selection.Requirements for bearings in engine compartment applications:

- Resistance to engine and gear oil

- Resistant to heat up to 200°C

- Resistant to particle abrasion

Advantages of our bearing technology:

- Cost advantages compared to needle bearings or metal-rolled bearings

- Vibration dampening

- No contact corrosion between housing and bearing

- Ideally suited in combination with plastic shafts

Suitable products

iglidur X

Extremely wear-resistant at high temperatures up to +250°C, very low moisture absorptionLearn more

iglidur H4

High chemical and temperature resistance -40°C to +200°CLearn more

iglidur H1

For high speeds and the lowest coefficients of friction in combination with plastic shaftsLearn more

Coupling joints

Custom dimensions and designs can be quickly implemented, easy to installLearn more

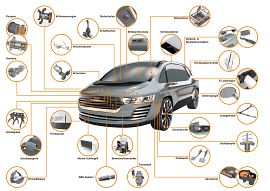

Further areas of application

Inside and outside: our dry-tech polymer bearing technology shows its advantages in many places in the car.Watch now

Go back to overview

To the introductory page with information on the advantages of our bearings and special servicesGo to overview