Technical data:

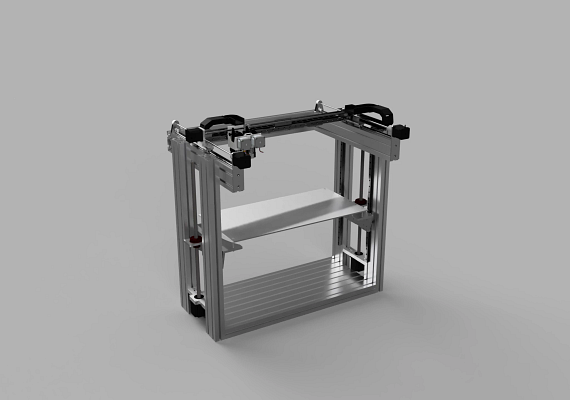

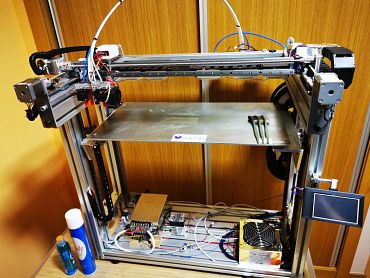

- What was needed: A large-format and precise 3D printer suitable for use in offices or workshops

- Requirements: Maintenance-free, easy installation, high accuracy, 100% lubrication-free, no adhesion of dust and dirt

- Products used: drylin® T rail guide and guide carriage with adjustment, dryspin® high helix lead screw and high helix lead screw nut, e-chain® energy chains

- Success for the customer: The engineers use linear guides, carriages as well as lead screws and lead screw nuts of the dryspin® type for the linear movements of all three axes. The lead screws allow travel speeds of up to 120mm/s. All components contribute to minimising 3D printer maintenance.

Need more information? Contact us here

Precise 3D printer with travel up to 120mm/s

Suitable for workshops and office facilities

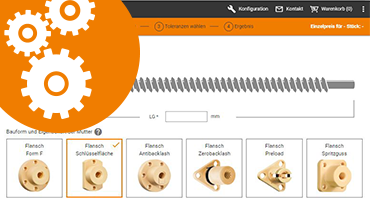

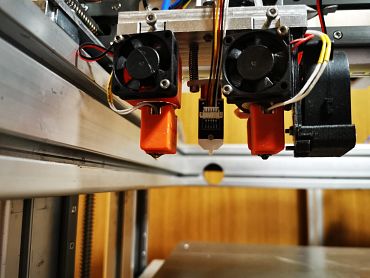

The environmental conditions of the 3D printer are cost-effective because they are indoor applications with good ventilation and stable temperature. Accordingly, no dust or dirt particles should adhere and the intention was to develop a maintenance-free machine.drylin® T rail guides, carriages with adjustment, dryspin® high helix lead screws and lead screw nuts were used. The iglidur filament was used for the production of customised lead screw nuts in the injection moulding process. In addition, the 3D printer cable chain has been upgraded to improve serviceability.

The igus® solutions are used for the linear movement in all three axes of the printer. The dryspin® high helix lead screws improve the precision and the energy chains offer an effective solution for guiding the electronic connections and protecting them. All parts help keep maintenance to a minimum thanks to high-performance polymers. Of particular note is dryspin® technology, which has made it possible to build the first 3D printer with high pitch lead screws. The dryspin® lead screws allow linear travel speeds of up to 120mm/s, which maintain or even improve the specifications of the belt transmission.

Products used

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here