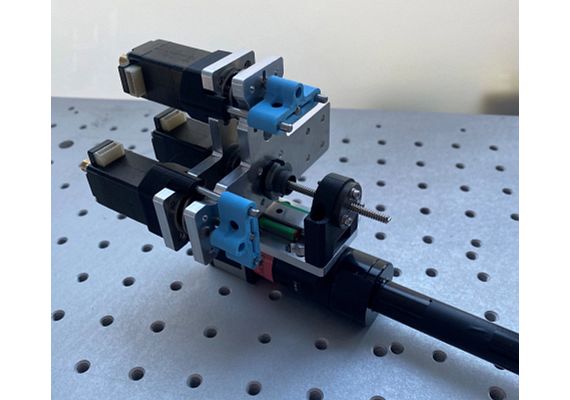

Precise panning of a microscope camera with 3D-printed clamps

Electrical micro-components additively manufactured using real-time imaging

igus, itself an additive manufacturing enthusiast, has supported XTPL with its 3D printing filament iglidur i151 in the implementation of the patented "Ultraprecise Deposition" technology. This allows, for example, the fine components of semiconductors and printed circuit boards to be printed using a micrometre-sized spray nozzle. Among other things, the real-time diagram of the printing process ensures that structures achieve a resolution of less than 1µm. A motorised camera system was developed for this, where clamps made of the slide-optimised filament ensured the stability and precision of the movement.- What was needed: Customised sliding elements as clamps for the moving linear actuators

- Manufacturing method: filament extrusion (FDM)

- Requirements: Dust-resistant, lubrication-free, lightweight, wear-resistant, chemical-resistant

- Material: iglidur® i151-PF tribofilament®

- Industry: Camera technology

- Success through collaboration: Ensures the promised printing accuracy, and cost savings thanks to the long service life of the wear-resistant sliding components

Find the right wear-resistant material for your application

Problem

In order for conductive structures, such as silver lines on printed circuit boards, to be cleanly guided out of the spray nozzle in the range of micrometres, the nozzle must move without deviation. So that this movement can be tracked in real time, the remote-controlled microscope camera needs to be panned just as accurately.In addition, the components of the camera system should be resistant to the solvent vapours released during printing and allow for lubrication-free movement. Another thing to consider was the use of lightweight components that reduce the inertia of the system.

Solution

Instead of the usual positioning of the camera along the XYZ axes using micrometres, a solution based on a spherical bearing was used, in which the camera lens deliberately pans within two planes. Clamps made by 3D printing were used to fix the aligning linear actuators, thus ensuring a stronger movement of the camera.In addition, the environmental conditions could be maintained thanks to the material properties of the iglidur i151 filament. Abrasion-resistant and lubrication-free, the lightweight plastic reduces inconvenient maintenance work. In addition, it has a higher chemical resistance compared to conventional 3D printing filaments.

A closer look at the structure

Smooth movement with igus bearing technology

Chemical resistance and freedom from lubrication had to be taken into account for all components of the camera system. Therefore, in addition to the 3D-printed clamps, further bearing technology from igus was used. As mentioned above, the pivoting of the microscope camera is mainly based on an igubal® clip bearing that is mounted on a fixed plate. The rotary plate is connected to the joint via an iglidur® G slide bearing. To eliminate clearance in the spherical bearing, a compression spring has been added that splays both plates apart. Moreover, the two plates are fastened with an intervening iglidur® G flanged bushing.

Are there other applications for which 3D printing is suitable?

As in the example above, additive manufacturing stands for creativity. When it comes to new product ideas or optimisations, there is a lot of experimentation, and a fast production method is a great advantage. Especially for sliding applications, prototypes or small volumes can be 3D printed relatively quickly and with a high degree of design freedom. With the 3D printing service from igus, the prices and specifications of different materials and printing processes can be compared. All that is required is a CAD file of the desired part.If the test component is successful in the appropriate application, the use of the 3D printer can go even further. Economical additive manufacturing processes, such as the laser sintering process, are also suitable for larger volumes. At igus, most parts are printed from wear-resistant, self-lubricating iglidur i3 plastic powder using the laser sintering process.

Upload model and compare manufacturing processes

Further application examples with components printed in 3D

All customer applications at a glance