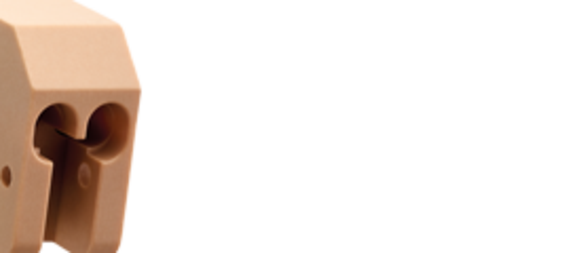

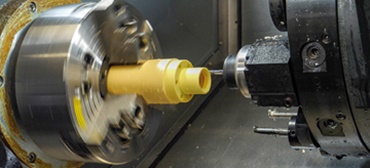

Components made of bar stock, turned, milled or drilled according to customer specifications

Bar stock turned or milled according to your specifications? No problem. igus® uses bar stock to manufacture components or prototypes individually according to your specifications, whereby the bar stock is in the form of round rods, hollow rods or plates and consists of iglidur® high-performance polymers. The production of profiles is also possible. What is special about iglidur® polymers is that they are especially wear-resistant and are maintenance-free. Best suited for quantities of: 1 to 500.

All igus® manufacturing methods at a glance

Special bearingsoverview page

Injection moulding

of special bearings

Special bearings

3D-printed

Injection moulding

with aluminium or

plastic mould

Your tailor-made iglidur® component in only three steps!

2. We turn, mill and drill holes in your component according to your specifications

The production process at igus® starts as soon as your order is received.

3. You receive your finished product

We make everything ready to ship and deliver your desired component as quickly as possible.

The right material for your project!

We offer you more than 50 tribologically optimised materials for innumerable applications in whichwear-resistance is a necessity. Irrespective of whether your application is exposed to high temperatures,

contact with media or wear-intensive conditions – igus® almost always offers a solution.

An overview of high-performance materials

Free sample box

The box contains samples and all the important information regarding individual, i.e. customised, components.Order the sample box free of charge!

Advantages of iglidur® materials

Each of our specially developed high-performance polymers possesses unique properties.More about the advantages

igus® bar stock online shop

Here, you can find all bar stock and information on the numerous iglidur® materials.Go to the online shop

Online tools

With the free online tools, you can calculate the service life of our products or configure them.Go to online tools overview

Application examples of our customers

Made of bar stock: special bearings for highest precision in ophthalmology

iglidur® bar stock is used to manufacture a microscope arm for eye examinations. The reason: it can be machined to produce customised plain bearings down to sizes measured in μm to ensure the necessary precision for examinations.

Perfectly fitting plain bearing made of bar stock

Made of bar stock: individual iglidur® component for melting probe

The "IceMole" is a melting probe, with which the polar regions, glaciers and as a long-term objective extraterrestrial regions are to be explored. For storing the ice screw, a component was needed that is water- and dirt-resistant and thermally insulated. Therefore, a bearing is used that was made of iglidur® A180 bar stock.

Media-resistant bearing for small installation spaces

Machined from bar stock: durable and wear-resistant plain bearings for finger prosthesis

This prosthesis is an electrically powered finger. The joint at the base of the finger is moved directly via a gear motor, which carries along the middle joint via a flexible connection. All axes involved in this movement are mounted through plastic sockets made of iglidur® J

. Altogether, eight bearings are integrated in one finger.

. Altogether, eight bearings are integrated in one finger.

Enables delicate movements

Printed in 3D: maintenance-free gripper for the packaging industry

Fast availability at a low price and use under hygienic conditions were important prerequisites for this 3D-printed gripper. It is used to package cosmetic products and has the special advantage of working without additional lubrication, hence fulfilling hygienic requirements.

More flexibility through 3D printing

Produced with injection moulding: bearings that compensate tolerances, in heavy-duty agricultural equipment construction

In the case of the agricultural machine construction industry, hay rakes are subjected to continuous stress in rough conditions. No problem for igus® special parts, however: not only are they particularly wear-resistant, they are also maintenance-free and reduce assembly costs.

In use for more than 20 years

Printed in 3D: customised plain bearing ready for collection within hours

What do you do when an important replacement part for an exhibit suddenly goes missing on the way to the trade fair? The response of the Berlin-based company Blackcam, a manufacturer of camera motion systems, is to turn to the igus 3D printing service.

Cost-effective and available quickly

Made of bar stocks: components made of iglidur® reduce maintenance costs

In a tyre soaping station, metal bearings were used up to now, which regularly led to a breakdown of the system. Now, these bearings have been replaced with plastic bearings made of igus® bar stocks . This saves costs of several thousand Euro per year.

iglidur® materials require no additional lubrication